Peanut butter, with a water activity level of 0.35 or less, is generally an unlikely environment for bacterial growth. Hence, it was not traditionally seen as a food prone to bacterial food poisoning. However, from 2006 to 2012, the United States experienced three major Salmonella outbreaks linked to peanut butter. At the time, President Obama appeared on NBC and made critical remarks about the FDA. This article presents an example of a study analysing the causes of one of these outbreaks.

Cavallaro et al.

Salmonella Typhimurium Infections Associated with Peanut Products.

N Engl J Med;365:601-10(2011)

Peanut Butter Food Poisoning Incidents

Between 1 September 2008 and 20 April 2009, a laboratory-confirmed outbreak of Salmonella Typhimurium infections was reported in the United States. This outbreak affected 714 patients across 46 states, with 166 cases (23%) requiring hospitalisation and 9 cases (1%) tragically resulting in death.

Investigators traced the outbreak to a single brand of peanut butter, referred to as Brand X. This product had been distributed to nine facilities linked to both clusters and isolated cases. Further studies revealed that the outbreak extended beyond peanut butter consumption at home. It also involved two brands of peanut butter crackers that utilised peanut paste from Brand X. The Salmonella strain responsible for the outbreak was identified in Brand X peanut butter, Brand A crackers, and 15 other products.

As a direct response to this contamination, 3,918 peanut butter-based products were recalled between 10 January and 29 April 2009, marking one of the largest recalls in the food industry.

Investigation and Analysis

Dr. Caballero and her team conducted a comprehensive investigation into the 2008-2009 Salmonella Typhimurium outbreak, carefully examining its causes and contributing factors. The findings highlighted key vulnerabilities at various stages of peanut butter production and distribution.

Raw Material Contamination

Salmonella contamination can occur at multiple points in the peanut supply chain. For instance, contamination may arise from soil through fertilizers or irrigation systems, as the bacteria can survive underground for months to years. Additional risks include cross-contamination during harvest, transportation, and storage from soil or water exposure.

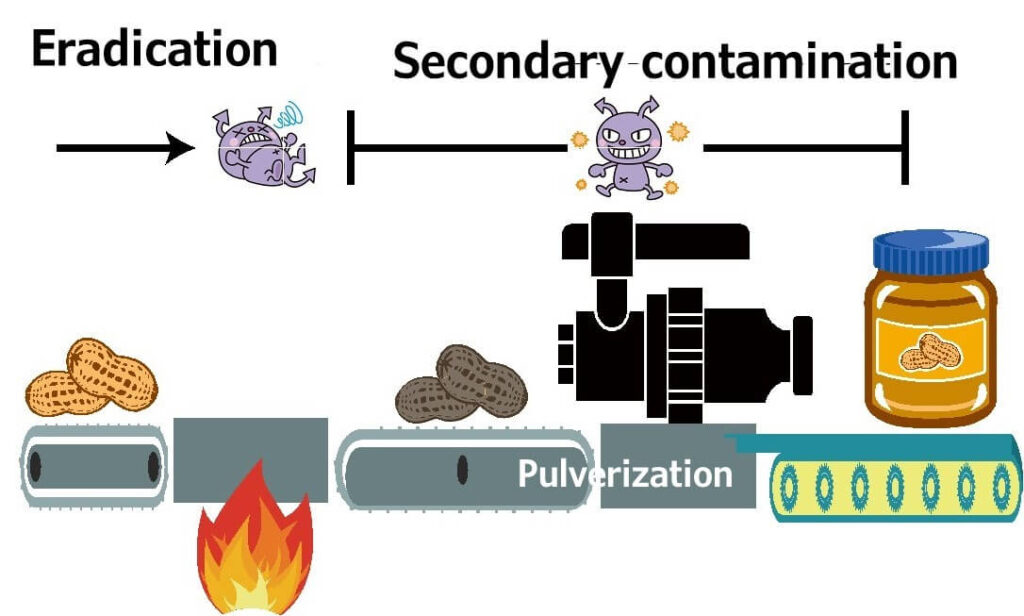

Even when raw peanuts are contaminated, they are typically roasted at approximately 180°C during peanut butter production—a temperature sufficient to eliminate Salmonella. However, any lapses during or after roasting can reintroduce the bacteria, posing significant risks.

Grinding Process

During the grinding process, roasted peanuts are processed at temperatures of 71-77°C for approximately 20 minutes. However, these conditions are insufficient to eliminate Salmonella if contamination occurs post-roasting. This highlights the critical need for stringent hygiene protocols during and after this stage to minimize contamination risks.

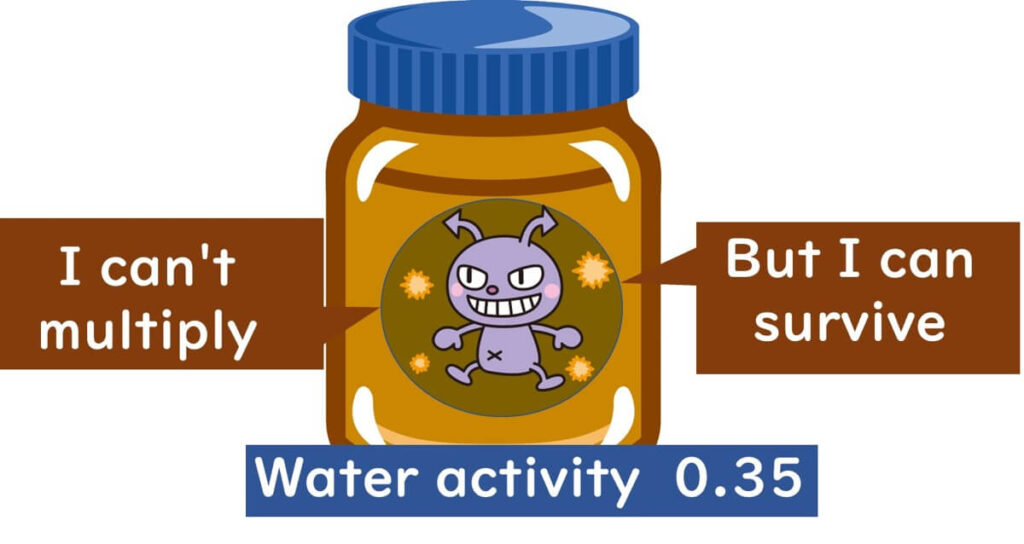

Distribution Process

Salmonella is capable of surviving in low-moisture environments, such as peanut butter, for extended periods—up to 24 weeks. If contamination occurs during or after production, the bacteria can persist throughout the product’s shelf life of 18-24 months. However, it is important to note that Salmonella cannot multiply under these conditions due to the product's low water activity.

The investigation concluded that the risk of Salmonella proliferation during the distribution of peanut butter is negligible. However, any contamination leading to foodborne illnesses likely originated within the manufacturing facility, emphasizing the need for robust preventive measures.

Why I Found This Paper Important

The Salmonella outbreak linked to peanut butter offers several valuable insights for food safety professionals. Here are two key reasons why this case stands out:

1. Salmonella Can Persist in Processing Facilities

Did you know that Salmonella can survive for extended periods in peanut processing plants? This long-term presence increases the likelihood of secondary contamination, which may occur even after initial roasting eliminates the bacteria. It underscores the importance of stringent hygiene measures throughout production.

2. Low Water Activity Doesn’t Eliminate Risk

Despite peanut butter having a very low water activity of 0.3—an environment where microbial growth is unlikely—Salmonella can still cause foodborne illnesses if reintroduced through secondary contamination. This highlights the unique risks posed by low-moisture foods.

These insights emphasize the importance of maintaining robust contamination control measures, even in products like peanut butter, traditionally considered low-risk. This case study not only challenges conventional assumptions but also provides practical lessons for improving food safety systems.

For those wanting to learn the basics about Salmonella, please see the following article:

Comprehensive Guide to Salmonella: Understanding Types, Risks, and Food Safety Measures

※The images and illustrations used in this article are intended to aid the reader's understanding of the case overview and are not related to any actual events or individuals.