Contamination of powdered milk by Cronobacter sakazakii and Salmonella poses serious health risks to infants. Preventing the introduction of Cronobacter sakazakii before the packaging stage is therefore essential for microbiological safety in powdered milk factories. To support this, understanding the bacterial flora in the production environment plays a crucial role in hygiene management.

This article introduces a study that monitored microbial communities in two powdered milk factories in Ireland over a two-year period using 16S rRNA amplicon sequencing technology. This is the first published investigation of bacterial flora in powdered milk factory environments using this method.

Cao et al.

A 16S rRNA sequencing study describing the environmental microbiota of two powdered infant formula built facilities

Foodborne Pathog Dis. 19(7):473-484(2022)

Most previous studies on microbial safety in powdered milk production have focused exclusively on pathogenic bacteria such as Cronobacter sakazakii and Salmonella, due to their significant risk to infants. Among these, Cronobacter sakazakii is especially prioritised as a critical foodborne pathogen.

However, because these pathogens are generally detected at low prevalence, relying solely on their detection is insufficient for daily hygiene control in food production sites.

For a detailed explanation of the challenges related to microbial testing for low-prevalence pathogens, please refer to the article below:

To address these limitations, broader microbial monitoring—including the detection of indicator organisms—is necessary. A highly effective tool for this is 16S rRNA amplicon sequencing analysis.

For an easy-to-understand explanation of16S rRNA amplicon sequencing analysis, please refer to the article below:

A research group led by Professor Fanning at University College Dublin (UCD) conducted a two-year study using this technique to monitor two powdered milk factories in Ireland.

Overview of Experimental Methods

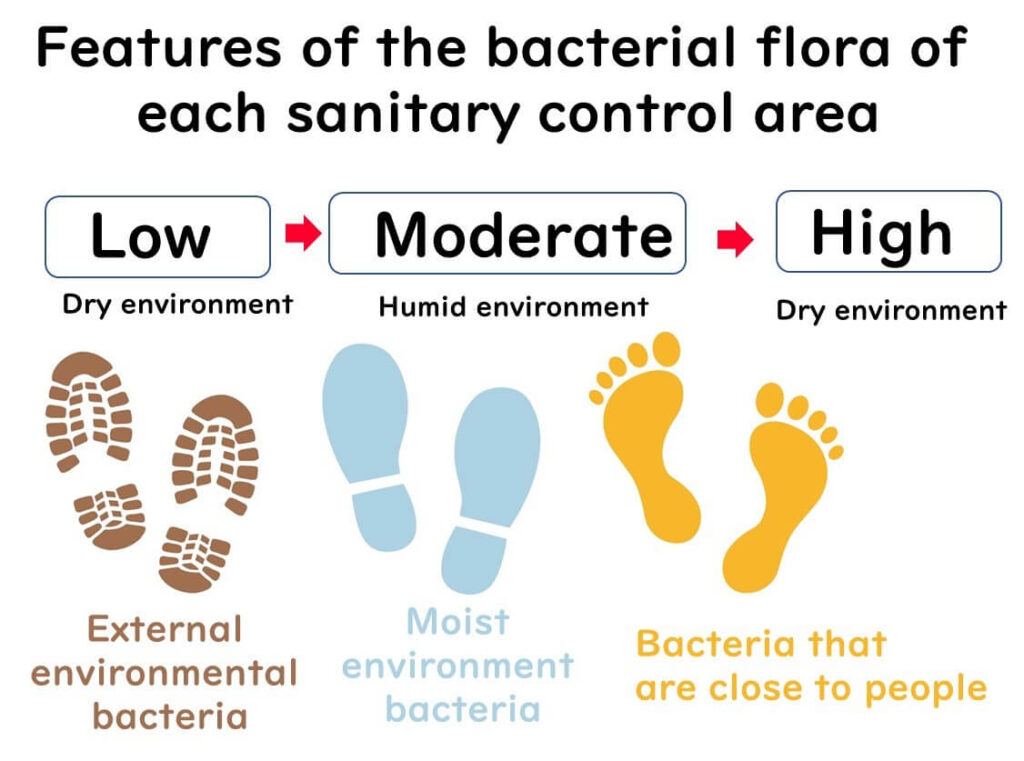

The study was conducted at two factories operated by the same powdered milk manufacturer in Ireland. Hygiene management within each factory was structured around three control zones:

- Low Hygiene Control Zone (Dry Environment):

This zone is exposed to people, traffic, and the external environment. - Moderate Hygiene Control Zone (Wet and Dry Environments):

Enclosed and strictly controlled, this zone enforces dress codes covering body, hair, and beard, along with routine weekly cleaning. - High Hygiene Control Zone (Dry Environment):

This zone requires enhanced personal protective equipment (face masks, gloves, and goggles) and undergoes frequent cleaning (twice daily).

Sampling points included floors, drains, equipment surfaces, and the soles of workers’ shoes.

- Environmental sampling was conducted monthly in both factories, yielding a total of 60 samples over the two-year period. All samples were analysed using 16S rRNA amplicon sequencing.

Summary of Results

At the genus level, the most commonly detected bacteria across all zones were:

- Acinetobacter (1.5–30.5% of samples)

- Pseudomonas (0.5–17.8% of samples)

- Unclassified members of the Pseudomonadaceae family (0.3–38.9% of samples)

As hygiene standards increased across zones, the composition of microbial communities shifted, creating distinct microbiota in each area:

- Low Hygiene Control Zone:

Dominated by environmental bacteria, such as Halomonas and Pedobacter, commonly found in marine environments, sludge, and soil. - Moderate Hygiene Control Zone:

Included both environmental bacteria and clinically significant genera such as Acinetobacter and Stenotrophomonas, particularly suited to moist environments. - High Hygiene Control Zone:

Showed a reduction in environmental microbes and a dominance of human-associated and food-related bacteria, such as Streptococcus and Staphylococcus. These genera are frequently associated with milk, dairy, and other fermented foods. The microbial flora in this zone was less influenced by the external environment and more by human activity and raw materials.

Cronobacter and Salmonella were detected, but only in trace amounts, indicating that hygiene management in both factories was generally effective.

However, other bacteria relevant to powdered milk safety—Acinetobacter, Clostridium, Staphylococcus, and Bacillus—were found even in the high hygiene control zone. These microorganisms are known for their resistance to desiccation and can persist in the dry conditions typical of powdered milk production.

My Take on This Study

What struck me most in this study is the clear evidence that even high-standard hygiene zones are not free from resilient, potentially harmful bacteria. From my perspective, the key takeaway is that environmental monitoring using 16S rRNA amplicon sequencing reveals microbial dynamics that conventional pathogen-targeted testing might overlook.

In particular, the presence of desiccation-resistant bacteria such as Acinetobacter and Bacillus in the high hygiene control zone highlights an underappreciated risk in dry production environments. These organisms are not only difficult to eliminate but may also colonise surfaces or raw materials, potentially compromising product safety.

For quality assurance professionals, this study reinforces the importance of holistic microbial surveillance across all hygiene zones, not just in wet or high-risk areas. Incorporating microbial community profiling into routine monitoring can help detect emerging issues early and fine-tune cleaning protocols accordingly.

This aligns with what I have seen in food industry settings—routine microbial data often fails to capture persistent low-level contaminants unless broader methods like amplicon sequencing are used.

This article is part of a series on individual case studies in microbial monitoring for hygiene management in food factories (Case Study 1, updated periodically).

For those seeking an introduction to environmental monitoring in food production, please refer to the article below:

📄The Importance of Environmental Monitoring in Food Factory Hygiene Management

For further information on Cronobacter sakazakii and its relationship with powdered milk, please see:

📄Understanding Cronobacter sakazakii: Risks, Prevention, and Safe Formula Preparation for Infants