In this article, we will delve into crucial research findings by USDA researchers on the relationship between the cooling rate of cooked rice and the growth of Bacillus cereus, and explore preventive measures against food poisoning caused by Bacillus cereus in detail.

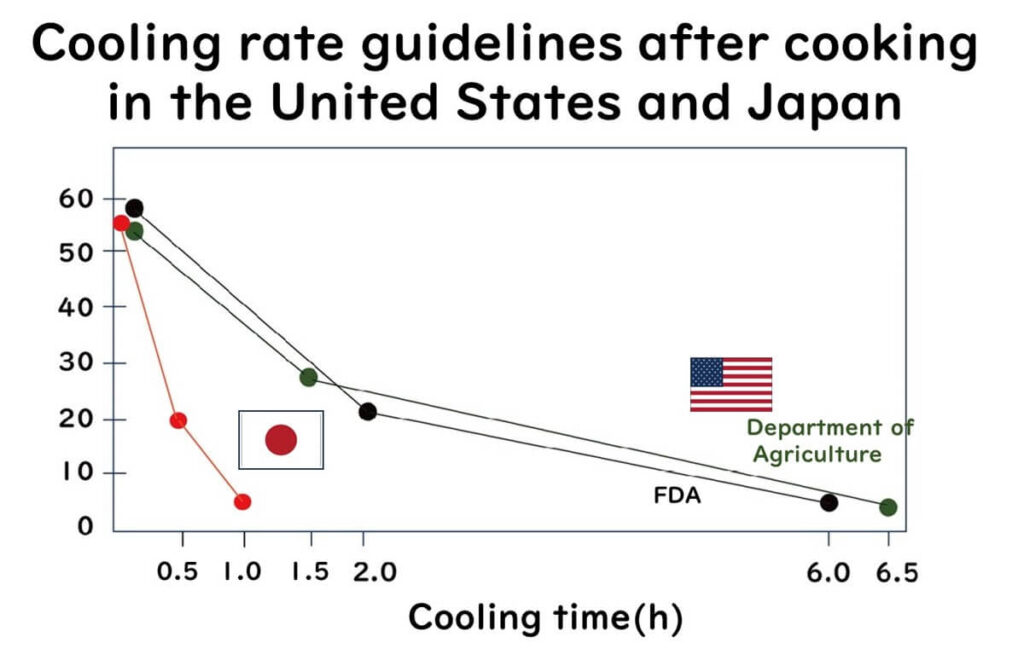

US and Japanese Guidelines on Cooling Rates After Heating

Firstly, let’s look at the US guidelines concerning cooling rates after heating.

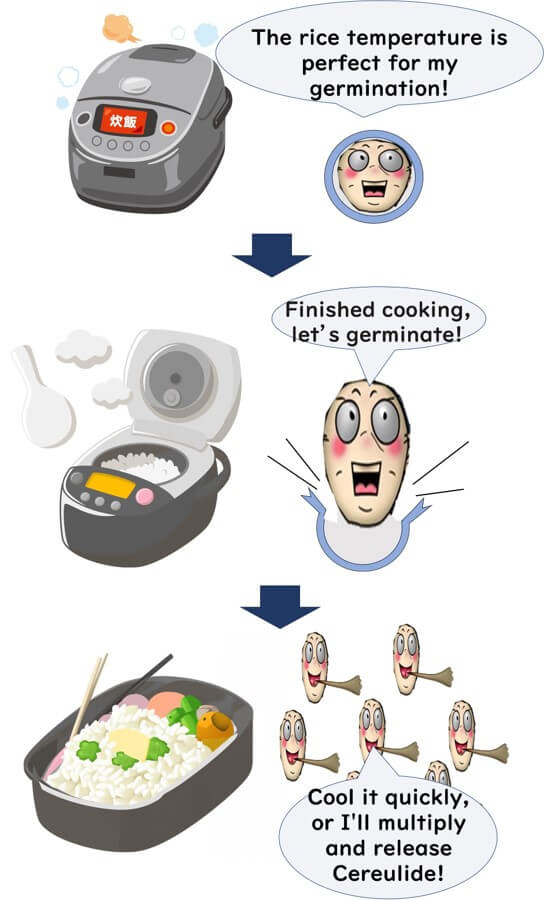

During the heating process of cooking rice, spore-forming bacteria can survive. If the cooling rate is too slow, these bacteria can germinate and potentially proliferate.

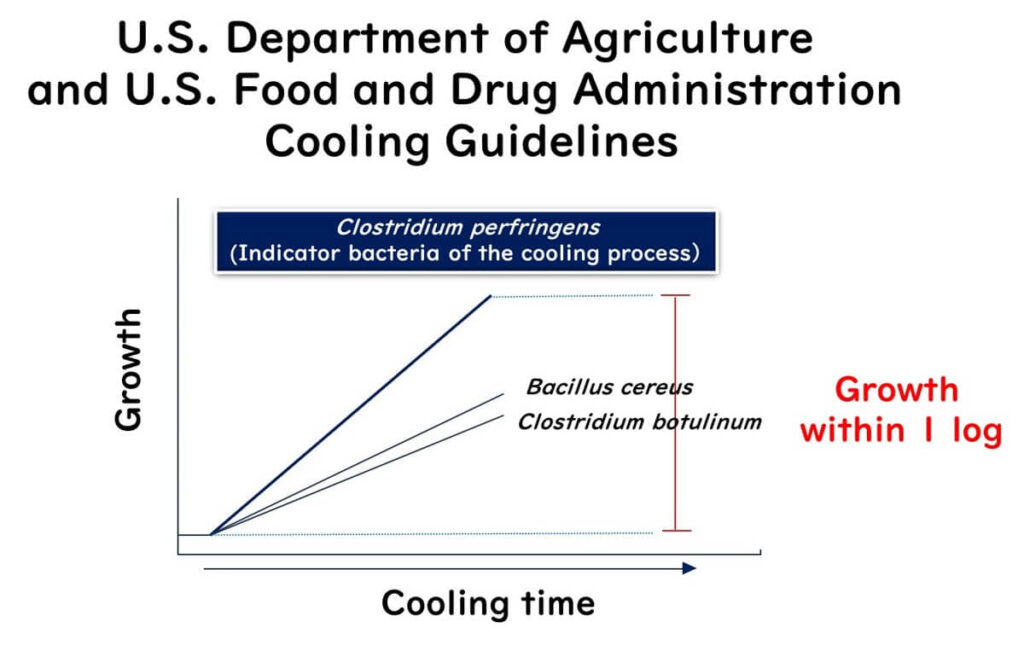

The primary risks come from Bacillus cereus, Clostridium perfringens, and Clostridium botulinum, with Clostridium perfringens posing the highest risk due to its rapid growth rate. Consequently, the USDA and FDA have established post-heating cooling guidelines to ensure that Clostridium perfringens growth remains under 1 log.

USDA Recommendations for Meat and Poultry Processing Products:

- Cool from 54°C to 27°C within 1.5 hours

- Cool from 27°C to 4°C within 5 hours

- Cool from 57°C to 21°C within 2 hours

- Then cool to 5°C within an additional 4 hours

In contrast, Japan has stricter guidelines. According to the "Manual for Hygiene Management in Large-Scale Cooking Facilities," it is recommended to cool heated food to below 20°C within 30 minutes and to below 10°C within 1 hour.

Understanding the Risk of Bacillus cereus Growth When Cooling Guidelines are Not Followed

As outlined, the USDA and FDA have established cooling guidelines based on the rapid growth rate of Clostridium perfringens. However, the risk of Bacillus cereus growth in high-starch foods when these guidelines are not followed had not been thoroughly quantified until recently.

Previous research had focused primarily on high-protein foods like ground beef. To address this gap, Dr. Juneja and colleagues at the USDA conducted a study to provide detailed data on how Bacillus cereus grows in high-starch foods such as rice, pasta, beans, and combination products when proper cooling procedures are not followed.

Juneja et al.

Influence of Cooling Rate on Growth of Bacillus cereus from Spore Inocula in Cooked Rice, Beans, Pasta, and Combination Products Containing Meat or Poultry

Journal of Food Protection Volume 81, Issue 3, 1 March 2018, Pages 430-436

Open archive

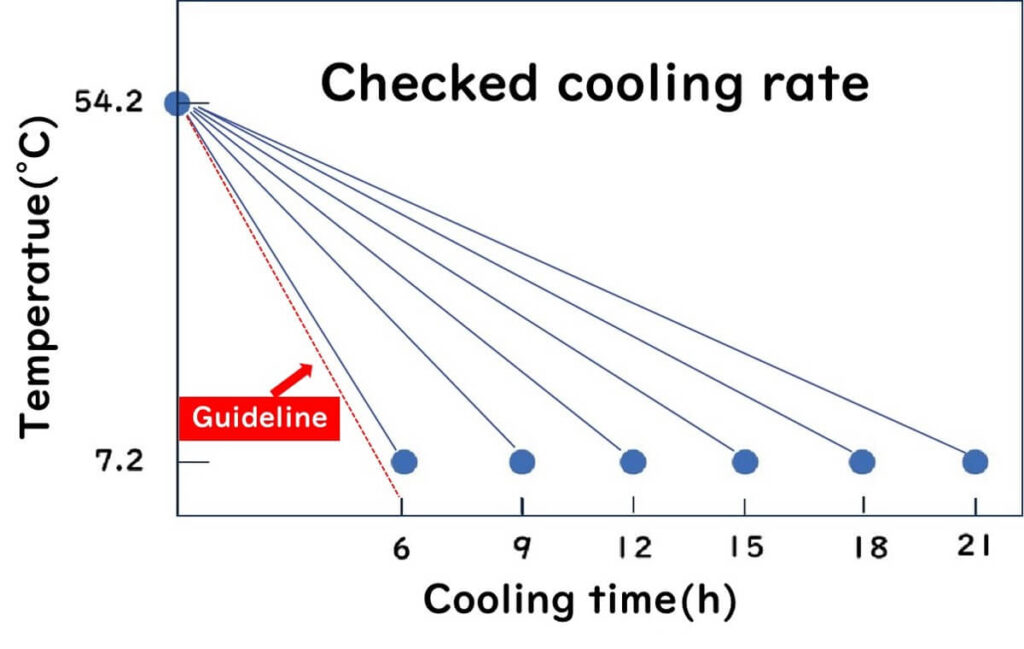

Experimental Overview

- The study aimed to determine safe cooling rates for cooked rice, beans, pasta, rice–chicken (4:1), rice–chicken–vegetable (3:1:1), rice–beef (4:1), and rice–beef–vegetable (3:1:1) by evaluating the germination and growth of Bacillus cereus spores.

- Samples were inoculated with a cocktail of four heat-shocked (80°C for 10 minutes) Bacillus cereus spore strains, resulting in a final spore concentration of approximately 2 log CFU/g.

- Cooling rates were designed to test growth when US guidelines are exceeded. Specifically, samples were cooled from 54.5°C to 7.2°C over 6, 9, 12, 15, 18, and 21 hours—reflecting real-world cooling scenarios in the US food industry.

Summary of Results

Bacillus cereus growth was faster in rice and pasta compared to beans.

- Beans: When cooled from 54.5°C to 7.2°C within 9 hours, Bacillus cereus growth was kept below 1.0 log. However, if cooled over 18 hours, growth increased to over 3 log CFU/g.

- Rice and Pasta: When cooled to 7.2°C within 9 hours, Bacillus cereus numbers increased by less than 1 log CFU/g. If cooling took over 15 hours, growth exceeded 3 log CFU/g.

USDA researchers highlighted that Bacillus cereus counts exceeding 3 log CFU/g (equivalent to 10⁵ CFU/g in rice) present a significant public health concern.

They concluded that the cooling rate data obtained in this study, conducted under conditions simulating retail and commercial food environments, can help food processors and foodservice operators manage microbiological safety in cooked foods more effectively.

My Take on This Study

What struck me most in this study is how clearly it demonstrates that the growth of Bacillus cereus during cooling can be significant even when adhering to current US guidelines designed with Clostridium perfringens in mind. From my perspective, the key takeaway is that high-starch foods like rice pose a greater risk of Bacillus cereus contamination than previously assumed, especially when cooling is delayed.

This finding challenges the assumption that US cooling standards are sufficient for all spore-forming bacteria. While a 1 log increase is often considered acceptable for Clostridium perfringens, the same margin may not be safe for Bacillus cereus—particularly when initial contamination is high. In this study, even with an initial level of just 2 log CFU/g, rice cooled over 9 hours exceeded a 1 log increase, approaching levels that may cause food poisoning.

From a food safety perspective, especially in quality control settings, this underscores the critical importance of rapid cooling—not only to prevent Clostridium perfringens growth but also to suppress Bacillus cereus. The Japanese guidelines, being more stringent, likely offer better protection and should be strongly considered in high-risk environments.

This confirms what I’ve long emphasised in food industry settings: cooling cooked rice and similar starchy foods quickly is not just best practice—it is essential to prevent Bacillus cereus food poisoning.

For a basic understanding of Bacillus cereus, please read the following blog article:

Bacillus cereus: Understanding Food Safety Risks and Effective Prevention