Heat sterilization is a cornerstone of food safety, categorized into two key methods: pasteurization and retort sterilization. In this article, we dive into pasteurization, demystifying essential concepts like D values and Z values, and exploring their practical applications. From theory to practice, learn how these tools ensure effective and safe food sterilization.

Sterilization Below 100°C (Pasteurization)

Pasteurization, named after the French microbiologist Louis Pasteur, is a method of heat treatment conducted at temperatures below 100°C. This process originated from Pasteur's experiments debunking the theory of spontaneous generation, where he sterilized liquids using a swan-neck flask. Unlike retort sterilization, which operates above 100°C, pasteurization is specifically designed for lower-temperature sterilization.

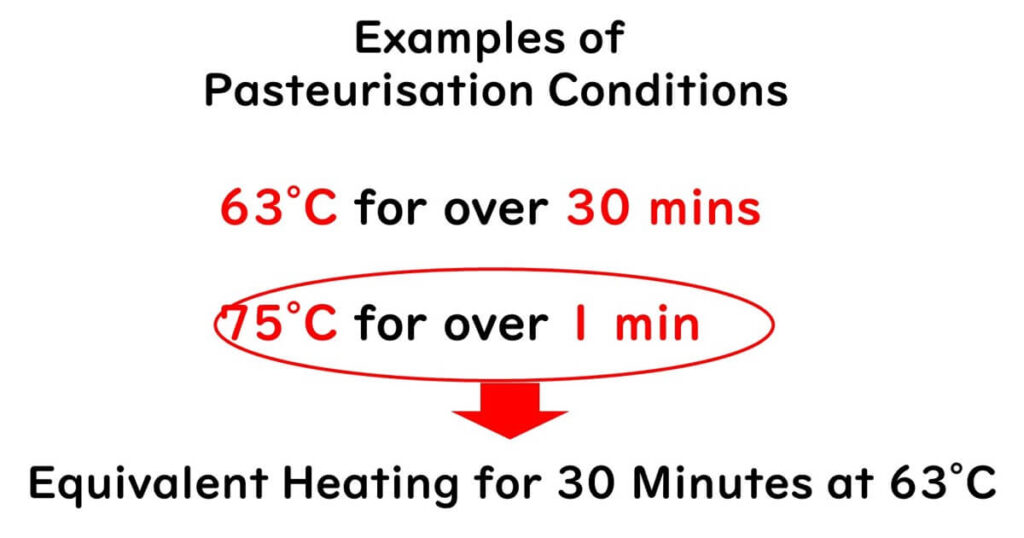

To ensure food safety, various countries have established pasteurization criteria. In Japan, the Food Sanitation Law specifies adequate heat treatment as maintaining a core temperature of 63°C for over 30 minutes or 75°C for more than a minute. Similarly, in the United States, pasteurization standards for milk include 63°C for 30 minutes or 71.7°C for 15 seconds. While these standards may vary depending on the type of microorganism and food, they share the universal goal of safeguarding public health.

Why Is the Pasteurization Temperature 63°C?

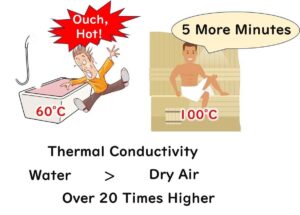

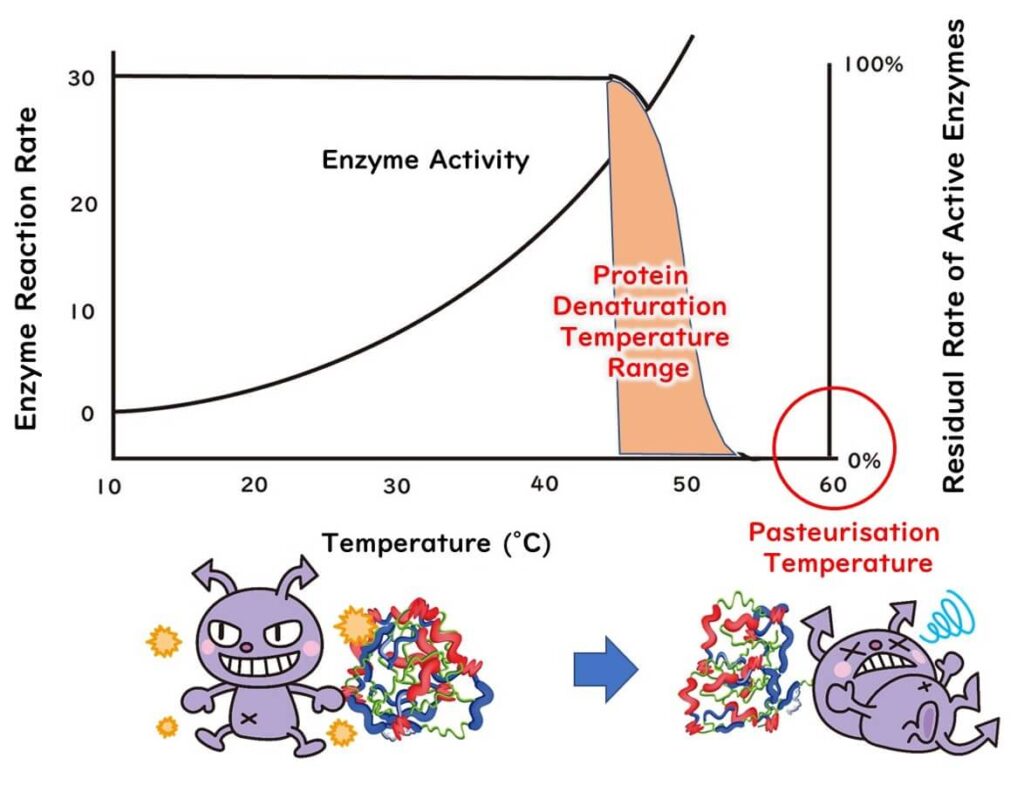

Ever wondered why 63°C is the go-to temperature for eliminating microbes through pasteurization? The answer lies in understanding the thermal denaturation of proteins. As the temperature rises, proteins begin to unfold and lose their original structure, leading to increased activities like enzyme reactions. However, at around 60°C, proteins lose their ability to return to their original shape, a process known as thermal denaturation. This critical point is why pasteurization relies on temperatures slightly above 60°C.

Since microbes are composed of proteins, denaturing these proteins effectively destroys them. The temperature of 63°C is specifically chosen to ensure that microbes are efficiently eliminated without compromising food quality.

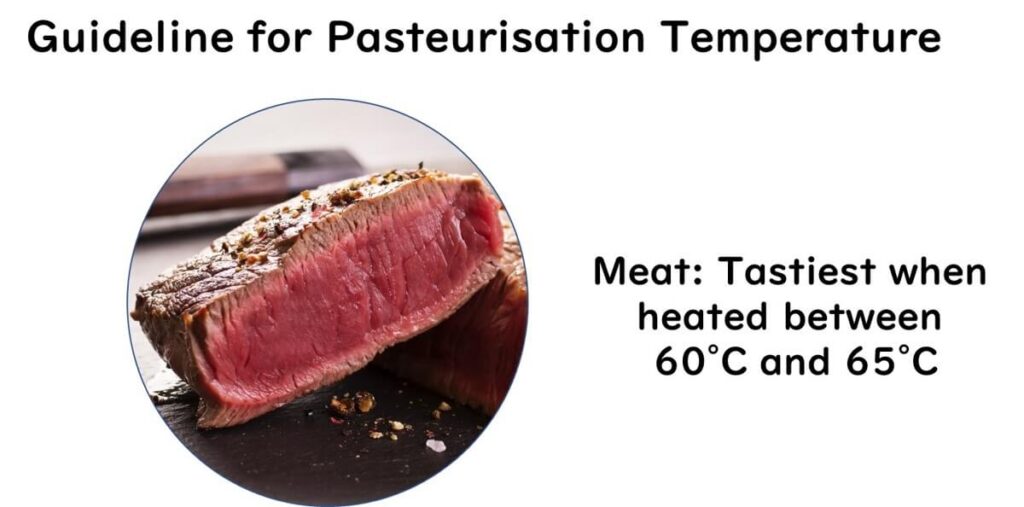

While higher temperatures can enhance sterilization, they also accelerate protein denaturation, potentially affecting food texture and flavor. For example, a steak’s core begins to change from red to white around 63°C, balancing microbial safety with maintaining its tenderness and taste. Going higher might kill all germs but could also result in overcooked, less enjoyable food. Thus, 63°C strikes the perfect balance, ensuring both effective microbial elimination and food quality.

Why the Pasteurization Time Is 30 Minutes

Why is 30 minutes the standard pasteurization time? While exact historical reasons for this choice are not entirely clear, insights can be drawn from the FDA guidelines in the United States. These guidelines specify pasteurization times based on the type of food and the target microorganism.

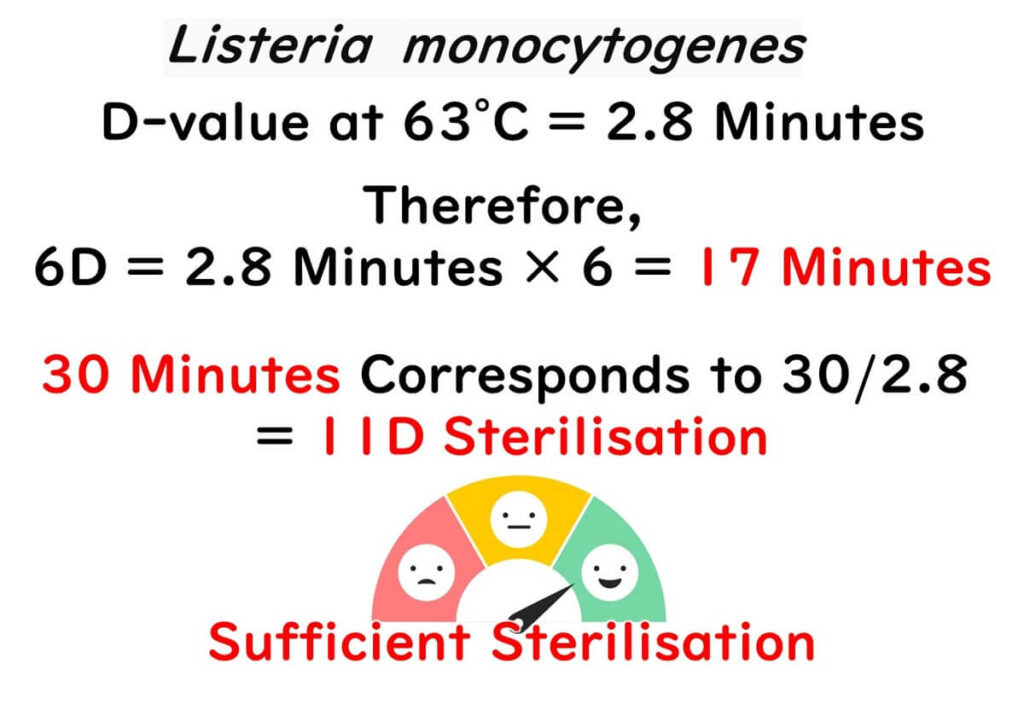

For example, in the case of Listeria monocytogenes in ready-to-eat foods, a 6 D reduction in bacterial count is required. This ensures a significant decrease in the microbial population, reducing the risk of contamination and ensuring food safety.

What Is a D Value in Heat Sterilization?

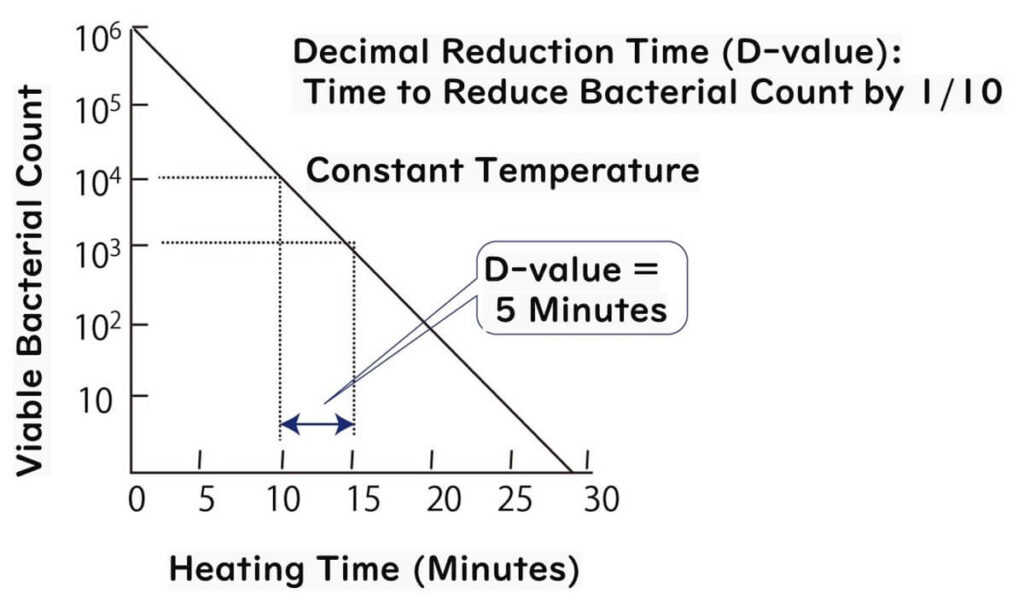

To understand the term "6 D", let's first clarify what a D value means.

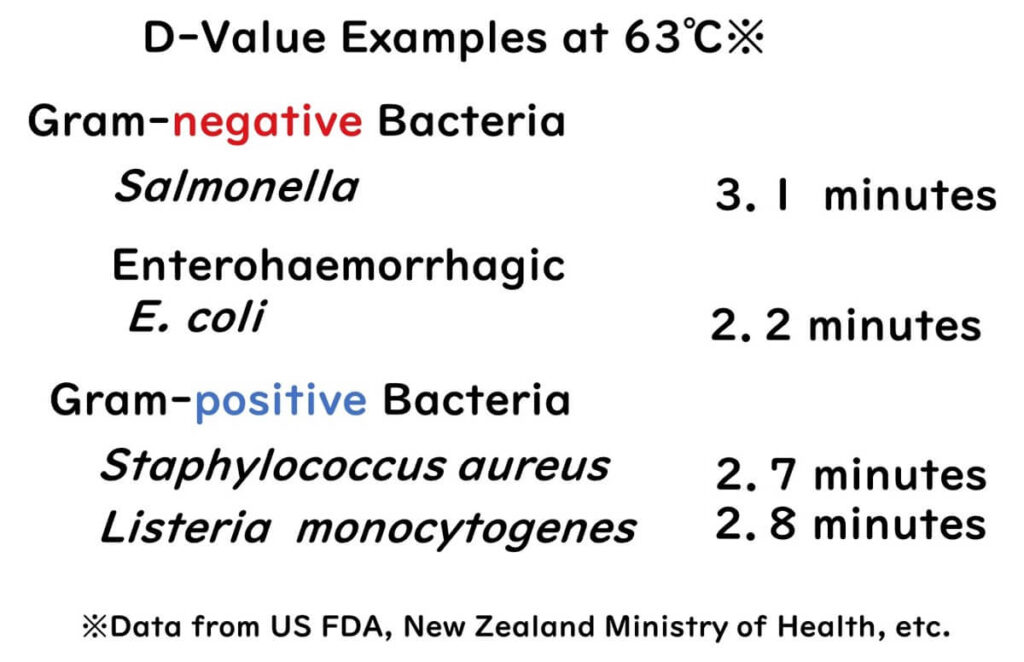

A D value represents the time required to reduce a specific microbial population by 90% (to 1/10th of its original count). For example, if the D value at 63°C is 3 minutes, it means that within 3 minutes, the microbial count decreases from 10⁷ to 10⁶.

But why does the FDA in the US specify a 6 D reduction for sterilizing ready-to-eat foods targeting Listeria monocytogenes? This requirement ensures that the bacterial population is reduced to safe levels. For instance, if a food product contains 10⁷/g of Listeria before heating, applying a 6 D sterilization reduces the count to 10¹/g, well below the minimum infectious dose. According to FAO/WHO (2004), food containing Listeria concentrations below 100/g is considered to pose minimal risk.

However, real-world conditions such as chilled distribution or improper temperature management can lead to bacterial growth. This is why foods with longer shelf lives or storage at 5°C for 10 days may require even higher D values to maintain safety. Pasteurization conditions are determined based on pre-sterilization pathogen counts, sterilization temperatures, distribution duration, and shelf life.

In the US, the zero-tolerance policy for Listeria mandates that it must not be detectable in any 25g of the product. For foods with an initial Listeria count of 10⁴/g, a 6 D sterilization ensures the count is reduced below detectable levels per 100g.

Significance of 30 Minutes at 63°C

The D value for Listeria at 63°C is approximately 2.8 minutes. A 6 D reduction requires 2.8 minutes × 6 = 17 minutes. Thus, a 30-minute pasteurization corresponds to an 11 D reduction, far exceeding the safety requirements, even in worst-case scenarios with an initial count of 10⁷/g.

Do D Values Vary Among Pathogens?

While D values can differ slightly between pathogens, they generally remain consistent across most microorganisms under similar conditions. This topic is further explored in later sections.

Note: The D values discussed here are derived from test-tube cultures and may increase in foods with low moisture activity.

One might wonder about pathogens other than Listeria. Generally, D values don't vary significantly among different pathogens, which we'll address further down.

Note: The D values mentioned here are standard values obtained from test-tube cultures. It's important to keep in mind that D values can increase in foods with low moisture activity.

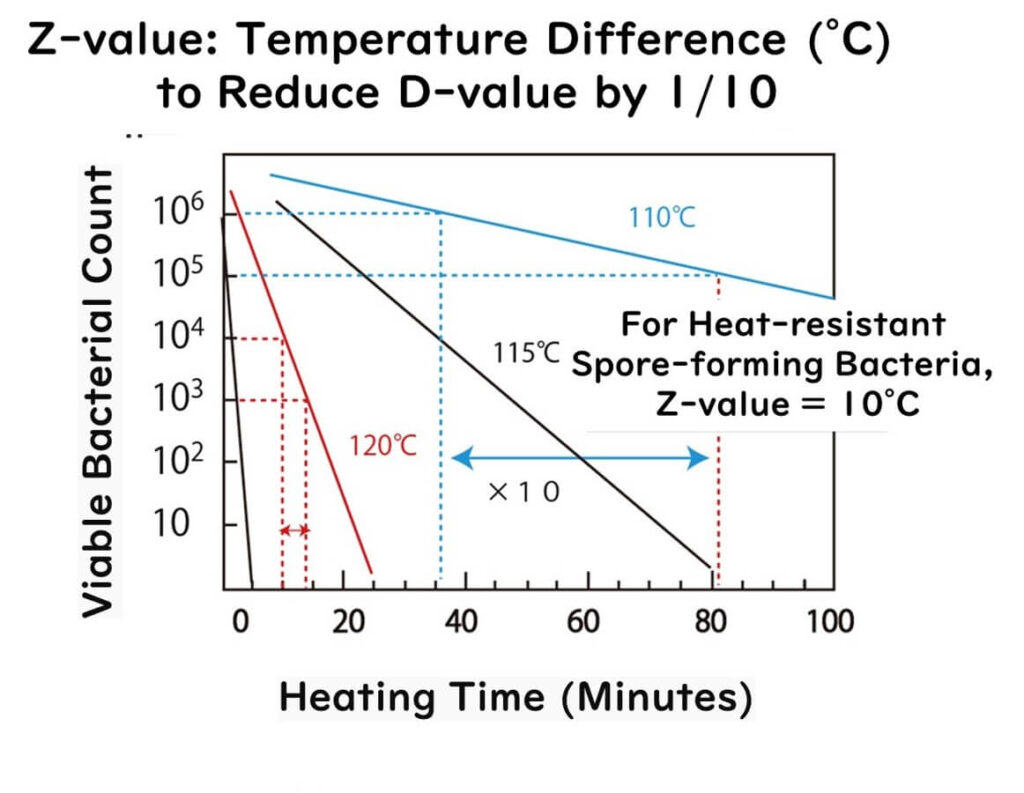

Understanding Z Values: Key to Calculating Equivalent Sterilization

When considering heat sterilization, understanding the Z value is essential for adjusting sterilization conditions effectively in food production. While it may initially seem theoretical, Z values have significant practical applications. Here's the definition:

Z value: The temperature change required to alter the D value by tenfold (in degrees Celsius or Fahrenheit).

This definition might seem abstract, so let's break it down with a practical example.

Practical Example of Z Values

Imagine adjusting sterilization conditions from 63°C for 30 minutes to a higher temperature with a shorter duration. If the temperature is raised to 71°C, and the Z value is 8, the sterilization time can be calculated as follows:

- An 8°C increase (from 63°C to 71°C) reduces the time by a factor of 10.

- Therefore, the sterilization time at 71°C is 30 minutes ÷ 10 = 3 minutes.

This calculation demonstrates how Z values help balance time and temperature in food sterilization.

Typical Z Values for Non-Spore-Forming Bacteria

For non-spore-forming bacteria below 100°C, Z values generally range between 5 to 8. Accurate Z values depend on specific data about:

- Microorganisms

- Sterilization conditions (temperature and time)

- Food properties

In this discussion, we use a Z value of 8 as a general reference.

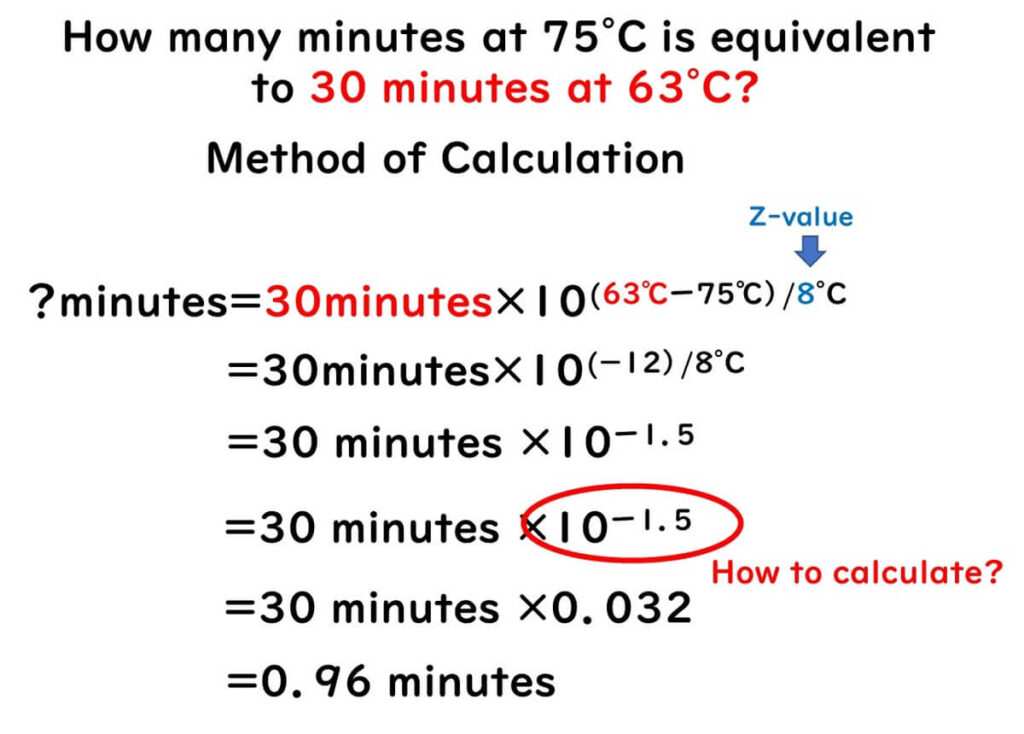

Using Z Values: Verifying 63°C for 30 Minutes vs. 75°C for 1 Minute

Now that we've covered the basics of Z values, let's apply them to a practical example. We'll compare two sterilization conditions: 63°C for 30 minutes and 75°C for 1 minute. Are these conditions truly equivalent in terms of sterilization? Using Z values, we can calculate and verify.

Formula for Sterilization Time

To determine the equivalent sterilization time, use the following formula:

Required sterilization time (minutes) = 30 minutes × 10^(63°C - input temperature) / 8°C

Here, the "input temperature" is the new temperature for which you want to calculate the required sterilization time. Let's work through some examples.

Example 1: Verifying 63°C for 30 Minutes

Start with the familiar condition of 63°C for 30 minutes:

- Input temperature = 63°C

- Substituting into the formula: 30 minutes × 10^(63°C - 63°C) / 8°C = 30 minutes × 10^0 = 30 minutes × 1 = 30 minutes

This confirms that the calculation aligns with the known condition.

Example 2: Calculating for 71°C

Next, consider a higher temperature of 71°C, which is 8°C above 63°C. With a Z value of 8°C, the sterilization time is expected to reduce by a factor of 10:

- Substituting into the formula: 30 minutes × 10^(63°C - 71°C) / 8°C = 30 minutes × 10^-1 = 3 minutes

This matches our expectation, showing that sterilization at 71°C requires 3 minutes.

Example 3: Verifying 75°C for 1 Minute

Finally, let's check 75°C, which is 12°C above 63°C. Using the same formula:

- Substituting into the formula: 30 minutes × 10^(63°C - 75°C) / 8°C = 30 minutes × 10^-1.5 ≈ 0.96 minutes

This calculation confirms that 75°C for 1 minute is nearly equivalent to 63°C for 30 minutes, validating the relationship.

Practical Application

By understanding this formula, you can adjust sterilization times for different temperatures in food processing scenarios while maintaining equivalent levels of microbial reduction. This ensures both safety and efficiency.

Tips for Easy Calculation

Calculating negative powers of ten can be tricky without a calculator or software like Excel. For practical use, consider using spreadsheets or tools designed for this purpose. A detailed tutorial on using Excel for these calculations is available in the linked video:

How Low Moisture Foods Impact D Values in Sterilization

When exploring D and Z values, a common question arises: how much do these values vary across different microorganisms? While it’s true that both D and Z values can differ depending on the specific microbe, a simplified approach can be more practical for everyday applications.

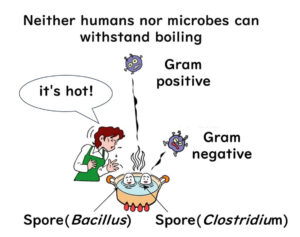

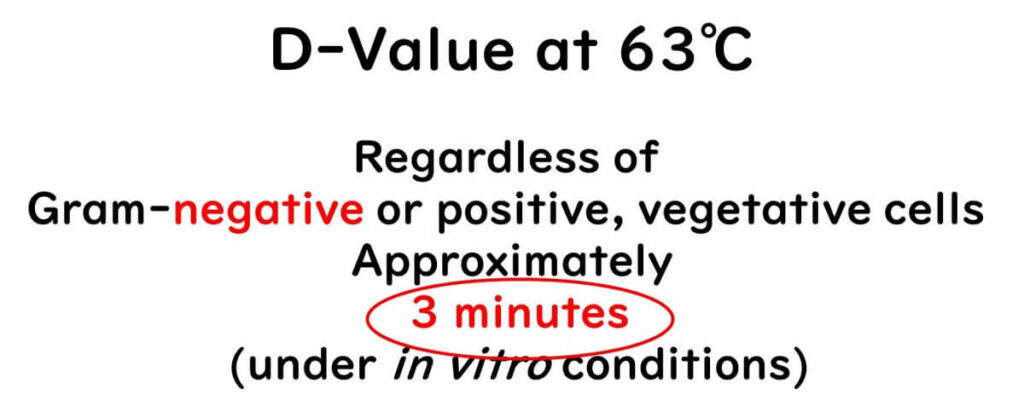

A Handy Rule for D Values: 3 Minutes at 63°C

For D values, it’s useful to remember a general guideline: 3 minutes at 63°C. At this temperature:

- Proteins in the vegetative cells of both gram-positive and gram-negative bacteria undergo denaturation, effectively neutralizing the microbes.

- This rule of thumb provides a practical reference point, minimizing the need for overly detailed calculations in many food safety scenarios.

General Guidelines for Z Values

While Z values also vary depending on the microorganism, the following generalizations are widely applicable:

- Below 100°C: A Z value of 8°C is commonly used.

- Above 100°C: A Z value of 10°C is typical, as seen in retort sterilization conditions.

For example, in retort sterilization at 121°C for 4 minutes, an equivalent sterilization at 111°C would require approximately 40 minutes. This demonstrates how Z values allow for adjustments in temperature and time while maintaining the same level of microbial reduction.

Understanding D Values: Why Low Moisture Foods Pose a Challenge

The D values discussed so far are primarily derived from liquid cultures, which are relevant for foods with a moisture activity (aw) above 0.9, such as vegetables and meats. In these cases, the D values provide a reasonable guideline. However, the scenario changes significantly for low moisture foods.

Impact of Low Moisture on D Values

In low moisture foods, the heat resistance of microorganisms increases substantially. This means that:

- D values from liquid media are insufficient for accurately assessing heat sterilization requirements in dry foods.

- Higher D values are necessary to ensure microbial safety in low moisture environments.

Further Insights

The relationship between moisture activity and microbial heat resistance is explored in greater detail in a related article. Understanding these dynamics is crucial for designing effective sterilization processes for low moisture foods.

Key Tips for Heat Sterilization and Experimental Design

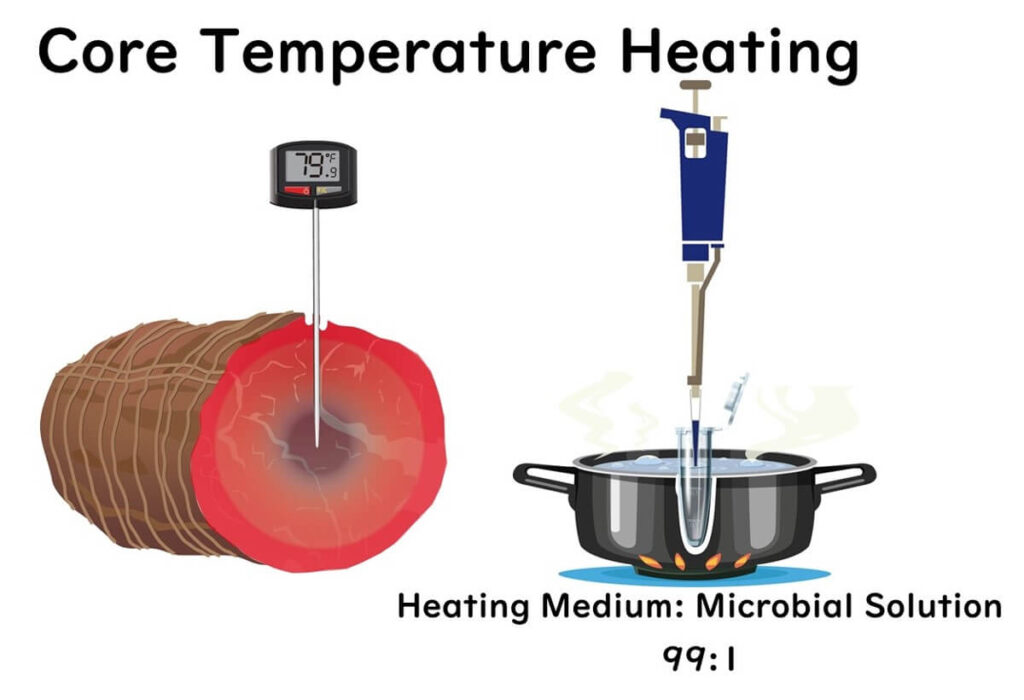

Heat sterilization requires careful attention to detail, particularly regarding core temperature control and time measurement. It's essential to note that all specified temperatures and times refer to the core temperature of the food, not the surrounding environment. For instance, when sterilizing meat at 63°C for 30 minutes, the temperature must be measured at the center of the meat. Using a thermometer to confirm that the core reaches and maintains 63°C for the entire 30-minute duration is crucial. Simply placing the meat in water heated to 63°C does not guarantee effective sterilization.

Another common mistake, especially in laboratory experiments, involves starting time measurements immediately after placing a test tube containing microbial cells into a water bath set at the target temperature. This approach often leads to inaccurate results since the cells are not instantly exposed to the desired conditions. A more precise method involves preheating 9.9 milliliters of culture medium to the target temperature (e.g., 63°C) and then introducing 0.1 milliliter of microbial culture. This ensures the microbial suspension is instantly exposed to the correct temperature, allowing for accurate tracking of microbial survival curves starting from time zero.

For those seeking more in-depth insights, additional articles on heat sterilization techniques, including foundational concepts and advanced methods such as retort sterilization, are available.

Understanding the principles of heat sterilization—especially the role of accurate temperature control and the effects of food composition on microbial inactivation—ensures the safety and effectiveness of food processing practices.

For a foundational understanding of heat sterilization principles and techniques, we recommend reading the article “Sterilisation of Food: Grasping the Basics of Heat Sterilisation” This resource provides essential insights into the science behind heat sterilization, including key concepts and practical applications.