Discover the rigorous science of retort sterilization, a pivotal technique in food safety that neutralizes the formidable spores of Clostridium botulinum at 121.1°C . This article explores the 'Botulinum cook' method, a specialized heat treatment that ensures the reduction of these dangerous spores in packaged foods, allowing for safe room temperature distribution. Join us as we unravel the balance between achieving maximum sterilization efficacy and preserving the quality and flavor of food, crucial for preventing foodborne illnesses.

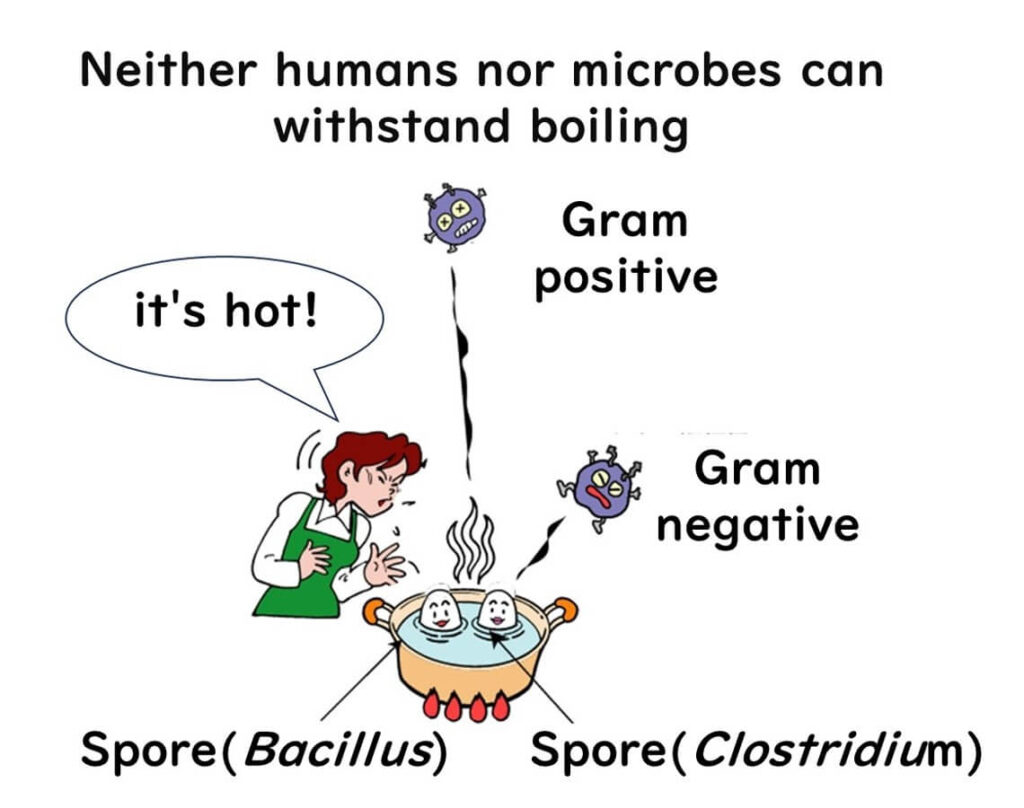

Thermo-resistant Spores That Survive Boiling at 100°C

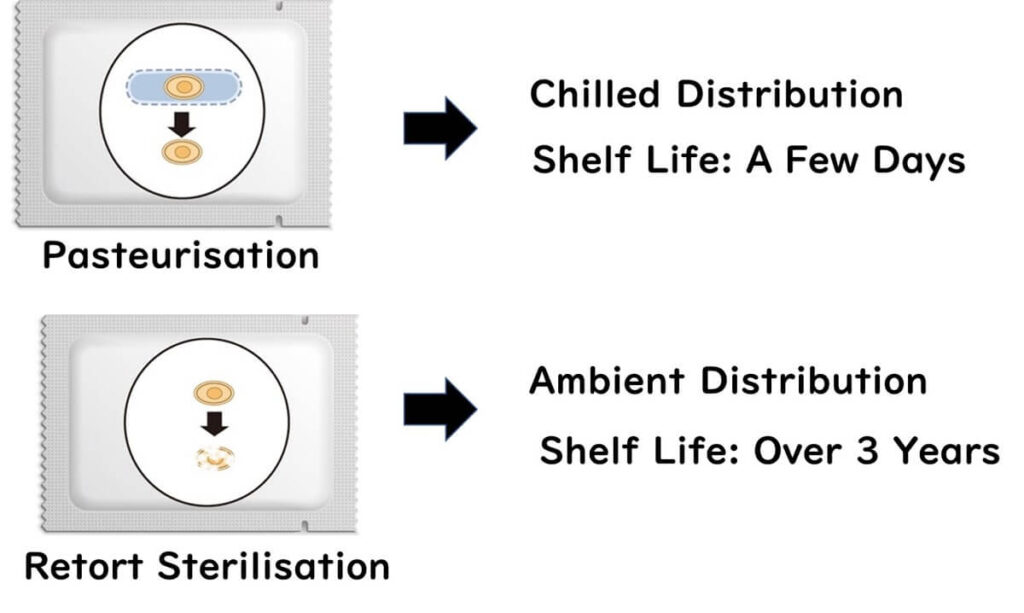

If you fully sterilize bacteria in food (i.e., sterilization), you can prevent microbiological spoilage, deterioration, or food poisoning—at least in theory. Such thoroughly sterilized foods are referred to as retort sterilized foods, and they pose no issues even when distributed at room temperature. However, strictly speaking, the definition of retort food doesn't necessarily imply it is sterile. For instance, certain ultra-thermo-resistant bacteria like Moorella thermoacetica do not die even at 121.1°C after 3 minutes. However, since their growth threshold temperature is around 50°C, they can cause flat sour spoilage in canned coffee sold in hot vending machines but are not a concern in normal room temperature foods.

In terms of bacteria related to usual room temperature foods, only two genera, Bacillus (to which Bacillus subtilis and Bacillus cereus belong) and Clostridium (to which Botulinum bacteria belong), possess notably high thermo-resistance. Therefore, targeting the spores of the highly resistant Botulinum type A bacteria for heat sterilization allows food to be packaged in sealed containers and distributed at room temperature.

What is Retort Sterilization (F4 Sterilization)?

For retort foods and canned goods intended to completely kill Botulinum spores, the concept of the F-value is crucial. An F-value of 4 in retort sterilization terms means applying a heat load equivalent to 4 minutes at 120°C to the center of the food. This amount of accumulated heating results in a reduction of Botulinum type A spores to the 12 D level, as evidenced by experimental data. The 12 D level implies a reduction in bacterial numbers to 10^-12.

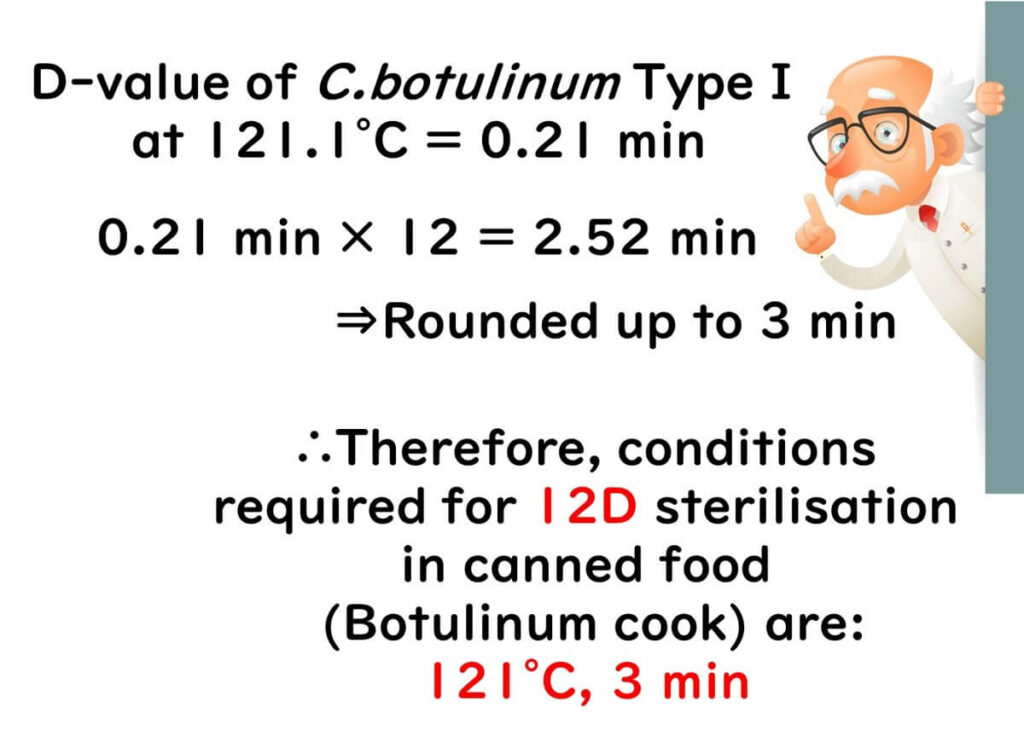

Sterilizing the heat-resistant spores of Botulinum bacteria is not possible with heating at 100°C; it becomes feasible only at 121.1°C. At this temperature, the D-value for Botulinum A spores is 0.21 minutes, a measured value obtained from experimental systems in test tubes. Hence, to achieve sterilization down to 12 decimal reductions, a sterilization time of 0.21 × 12 = 2.52 minutes is necessary.

Internationally,

- 121.1°C for 3 minutes is the stipulated condition for the 12 D sterilization of canned foods, also known as the Botulinum cook

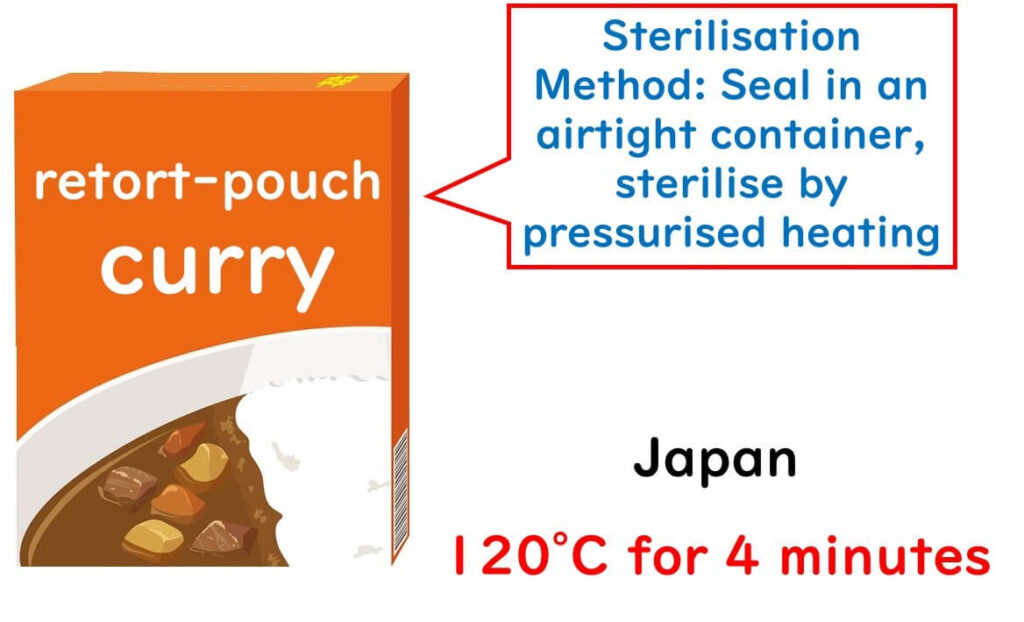

On the other hand, Japanese food sanitation laws specify a heat treatment equivalent to 120°C for 4 minutes.

What is the Theoretical Basis for 12D Sterilization?

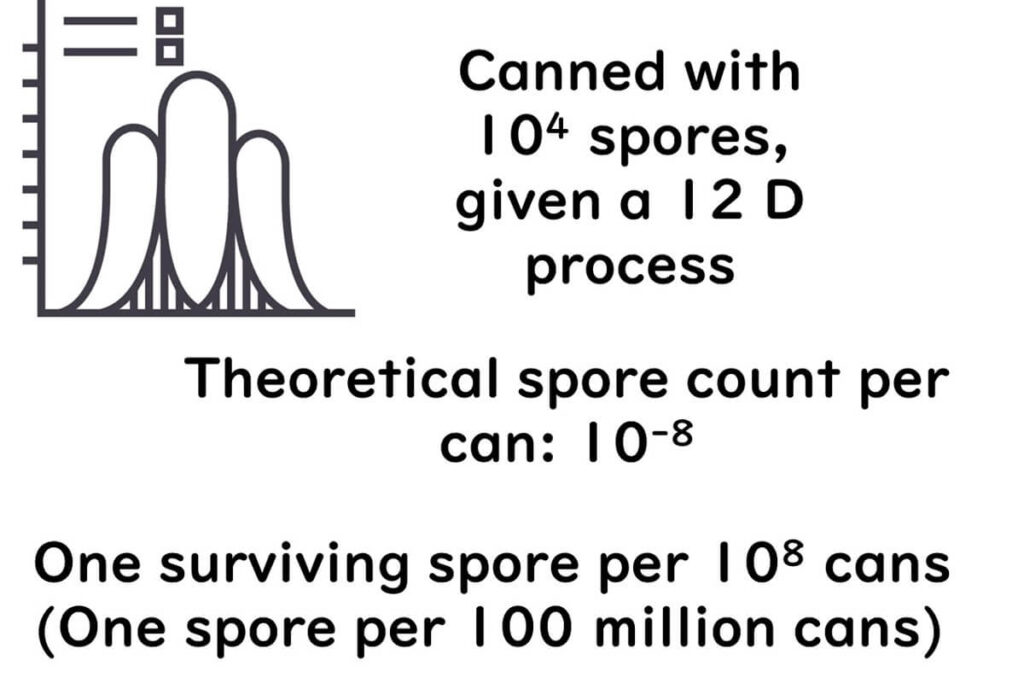

Alright, let's dive into why it's all about 12D sterilization. Imagine, for a moment, you've got a bag of retort food with 10^6/g of Clostridium botulinum spores present. Apply a 12D sterilization process, and the number of spores per bag drops to 10^-6/g. In other words, you'd have to manufacture 1 million bags to find one where a botulinum spore survives. Usually, you're not shipping out a million bags at a time, so this level of sterilization ensures safety, according to the logic.

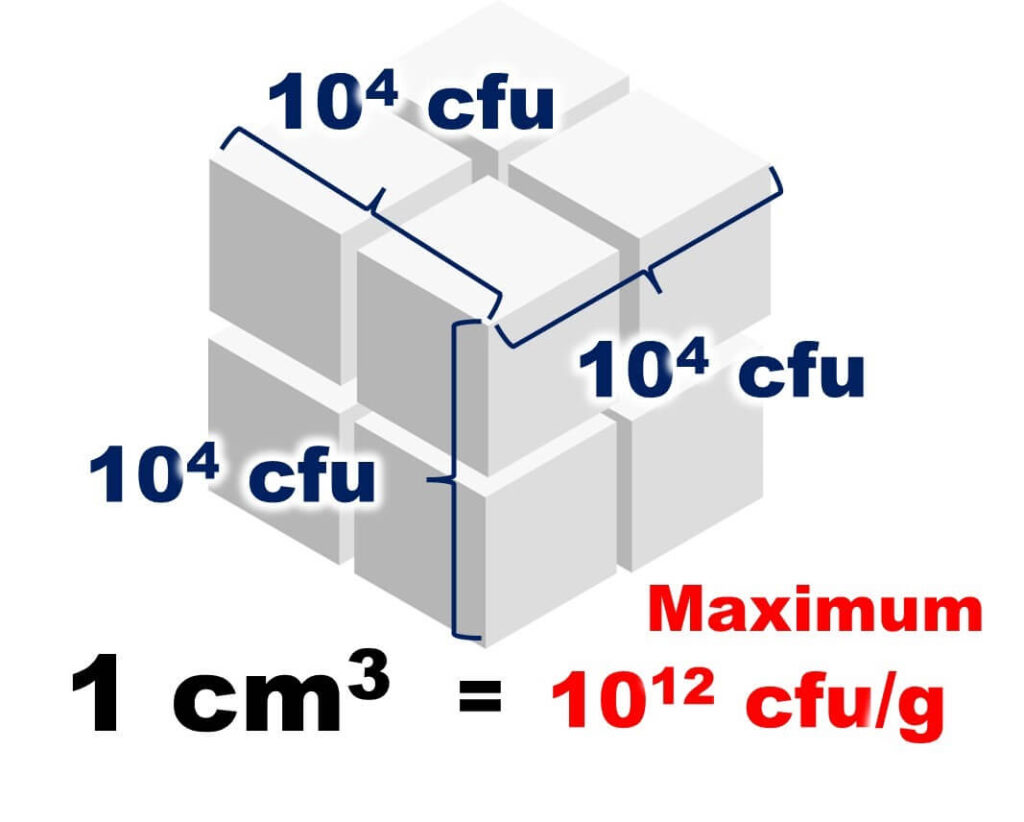

So, why do we start off assuming there are 10^6 spores per gram? To get this, you need a rough idea of the usual bacterial levels in food. As explained in our basic series, "Microbial Counts Around Us (General Aerobic Counts)", fresh fish, meat, or vegetables have about 10^3 microbes per gram. If spoiled, this number rises to 10^7. And our feces? They pack about 10^12 to 10^13 microbes per gram. If you filled a cubic centimeter entirely with microbes, you'd reach these figures—any higher concentration is pretty much impossible.

With this understanding, it makes sense to consider the worst-case scenario in retort products where botulinum spores are assumed to be at 10^6/g. Even if we don't assume our food volume is entirely made up of microbial cells like feces, considering spoiled food could realistically reach 10^7/g or even 10^8/g. However, if there are 10^7 to 10^8 microbes per gram, the product would stink of decay, and it's unlikely it would ever be packaged that way. But if we hypothetically considered these figures, applying 12D sterilization, as explained earlier, would obliterate the botulinum spores completely.

For an even simpler understanding, consider if the packed food was crammed only with botulinum spores. At most, there would only be 10^12 spores per gram. So, even if the entire content of a packaged food was botulinum spores, theoretically, 12D sterilization would wipe them all out—a helpful way to grasp the concept, perhaps!

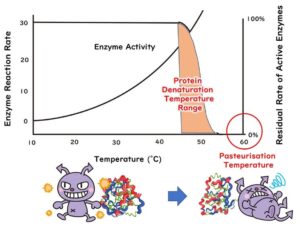

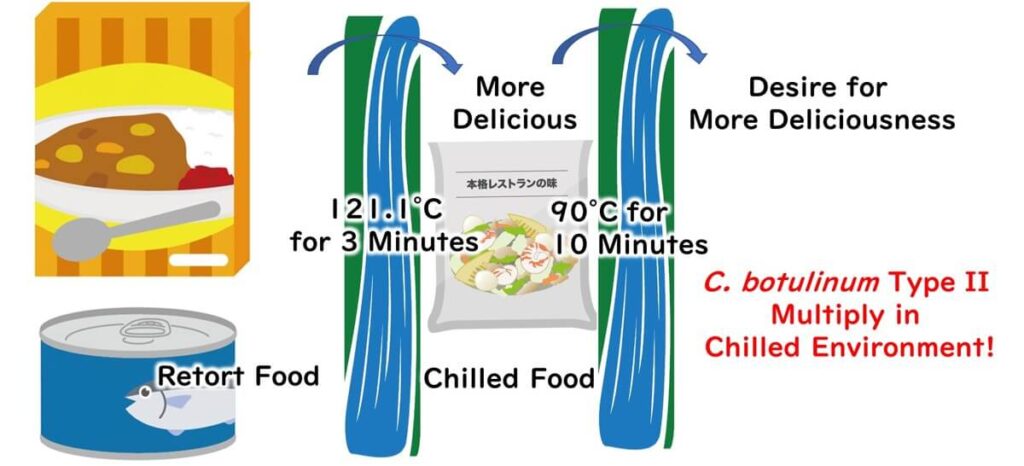

Non-F4 Sterilized, Relaxed Heat Treatment for Chilled Packaged Foods

Let's touch a bit on the product development of foods related to heat sterilization. As previously mentioned, retort foods are typically subjected to high temperature and pressure cooking at 121.1°C for 3 minutes. Such high heating temperatures, however, can degrade the food's flavor. For instance, meat processed under these conditions becomes very tough. Consider when you visit a steakhouse; you are asked whether you prefer your steak well-done, medium-rare, or rare. The medium-rare level begins just as the redness in the cut starts to fade, and this occurs around 60°C for about 30 minutes—this slight denaturation of proteins is what makes meat taste best. Thus, the intense heat treatment used in retort products, like 121.1°C for 3 minutes, makes the meat tough and less tasty. From a safety standpoint concerning botulism, sterilization is a must for retort products. However, from a palatability perspective, it's far from ideal.

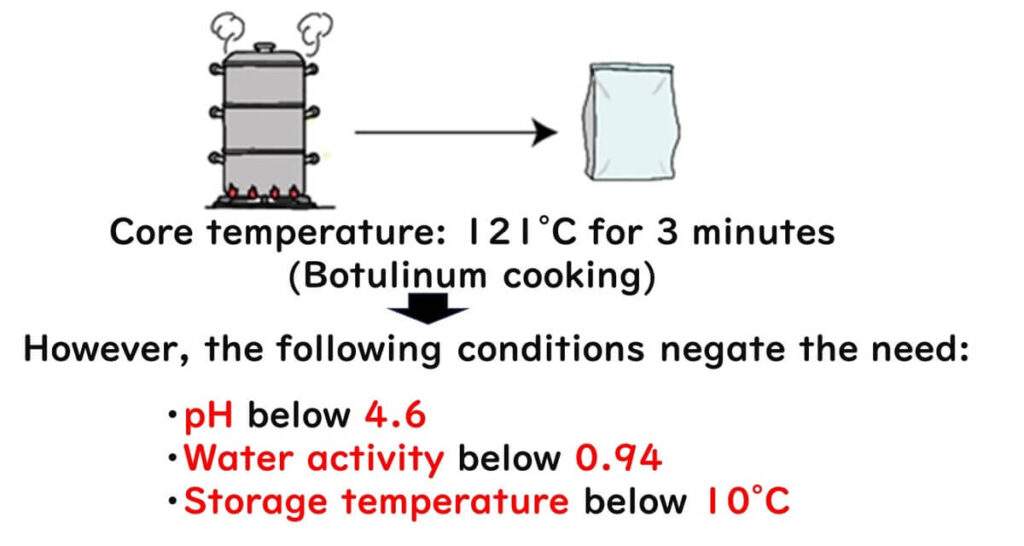

To create tastier packaged foods than retort products, an alternative to 121.1°C for 3 minutes of heating exists. However, as we have discussed, without such heat treatment, Clostridium botulinum type I spores cannot be eradicated. Yet, there are certain conditions under which food products can be distributed even if the heat-resistant spores survive. Let's explore these conditions.

Firstly, consider pH levels. If the pH of a food product is below 4.6, Clostridium botulinum cannot grow. Such products do not require heating at 121.1°C for 3 minutes. Typical examples include canned mandarins.

Another condition involves water activity, which is less than 0.94. Water activity will be detailed in upcoming articles in this series, but for now, it's enough to understand it as a measure of water available for microbial use in foods. A low water activity means it's hard for microbes to proliferate. If the water activity is below 0.94, many pathogens, including botulinum, cannot grow. Therefore, no intense heat treatment like 121.1°C for 3 minutes is necessary for such products. Examples include jams and dried shiitake mushrooms.

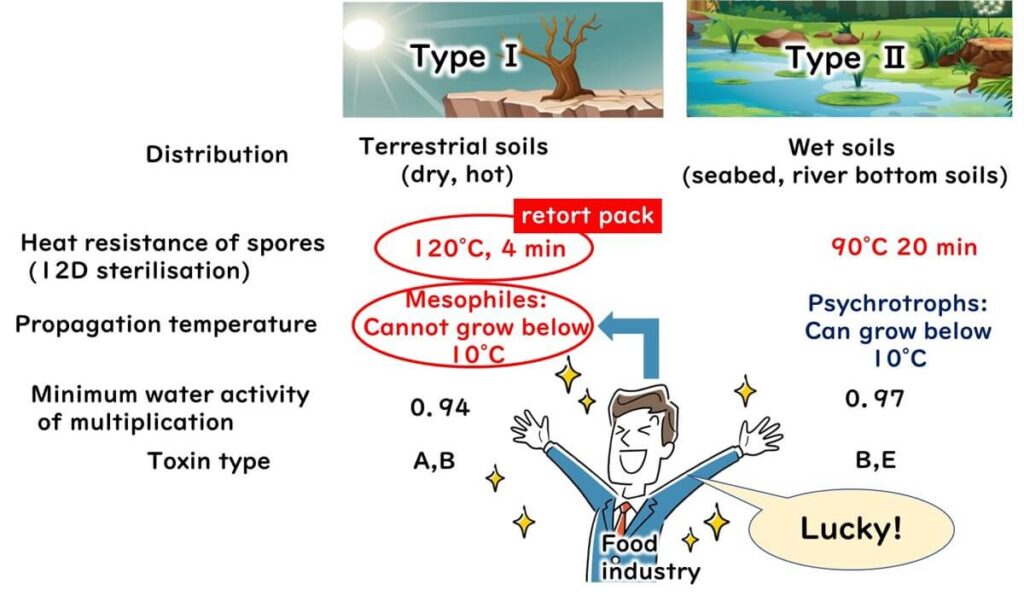

Finally, consider the distribution temperature of packaged foods below 10°C. Even without heating at 121.1°C for 3 minutes, if the food is distributed below 10°C, the risk of botulinum poisoning can be mitigated. As will be discussed later, while some types of Clostridium botulinum can grow at low temperatures, Type I cannot. Most soil microbes, which include botulinum, can grow below 10°C, essential for decomposition and nutrient cycling in winter. However, some microbes, like those belonging to the Type I botulinum, do not grow at such low temperatures—they are somewhat akin to summer fungi.

This trait has proved fortuitous in the world of food development. Even if Type I Clostridium botulinum spores survive in packaged food, the risk can be managed by distributing the food chilled. Thus, this principle allows for the distribution of chilled foods with relaxed heating requirements, avoiding the need for intense 121.1°C, 3-minute heat treatments.

It's crucial to underscore that the success of such products hinges significantly on "chilled management." This doesn't just mean that without proper chilling, the product won't last long; it means that without it, consumers risk exposure to botulinum toxin, one of the most lethal toxins on Earth.

Indeed, there was a serious incident in Japan in 1998 involving a family who consumed Hayashi rice—a stew similar to curry rice, packaged and sterilized in a bag. The product had undergone a relaxed heat treatment process, less than the usual 121.1°C for 3 minutes (Japan's regulations specify 120°C for 4 minutes), and was intended for chilled distribution. However, the family kept the product at room temperature for three days during a hot summer and subsequently consumed it, leading to severe botulinum poisoning that left a sixth-grade girl and her parent in a critical, unconscious state.

This case highlights a significant issue: before 1998, nearly all packaged curry products were retort-packaged, meaning they were safe for ambient storage. Consumers accustomed to these products might not consider the grave risks of improperly storing chilled products, assuming at worst slight spoilage rather than lethal contamination.

As a result of this incident and recognizing that consumers may confuse these products with ambient-safe retort items, Japan's Ministry of Health, Labour and Welfare issued a directive requiring that chilled products prominently display a "requires refrigeration" label in large, 14-point text or larger. This labeling is critical; without it, the product would be in violation of food safety laws. Even though the product in question did have the required labeling, the tragedy underlined the potential dangers due to consumer misunderstanding and the necessity for heightened awareness and clear communication in product packaging and consumer education.

Can We Relax Heat Sterilization Conditions for Tastier Packaged Foods Containing Botulinum Type II Spores?

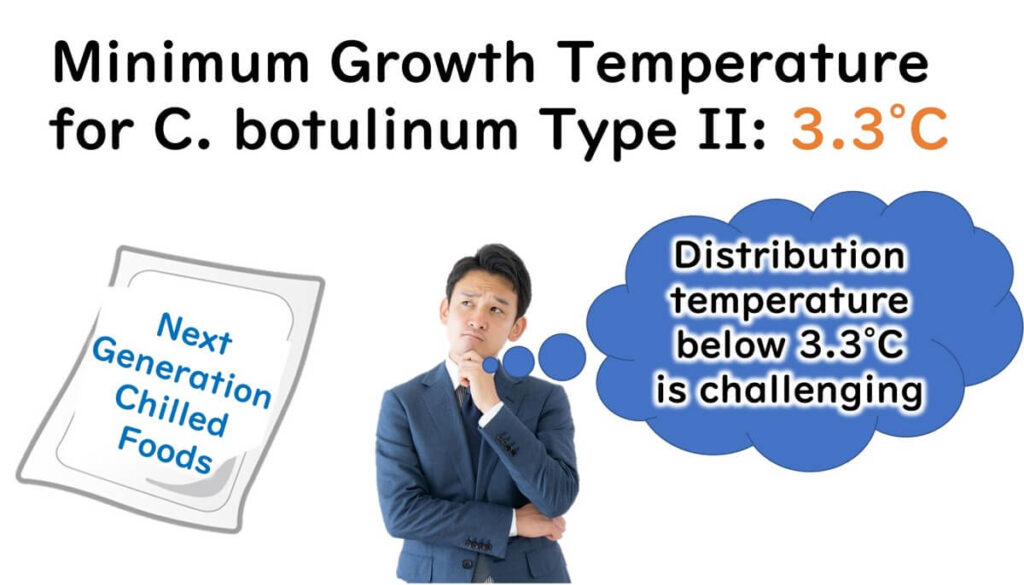

In the section on Clostridium botulinum, we discussed the two types of the bacterium. Type I, which requires heating to 121.1°C for 3 minutes due to its heat-resistant spores, cannot grow below 10°C. As mentioned, lowering the heat treatment requirements while ensuring distribution below 10°C can mitigate the risks associated with Type I.

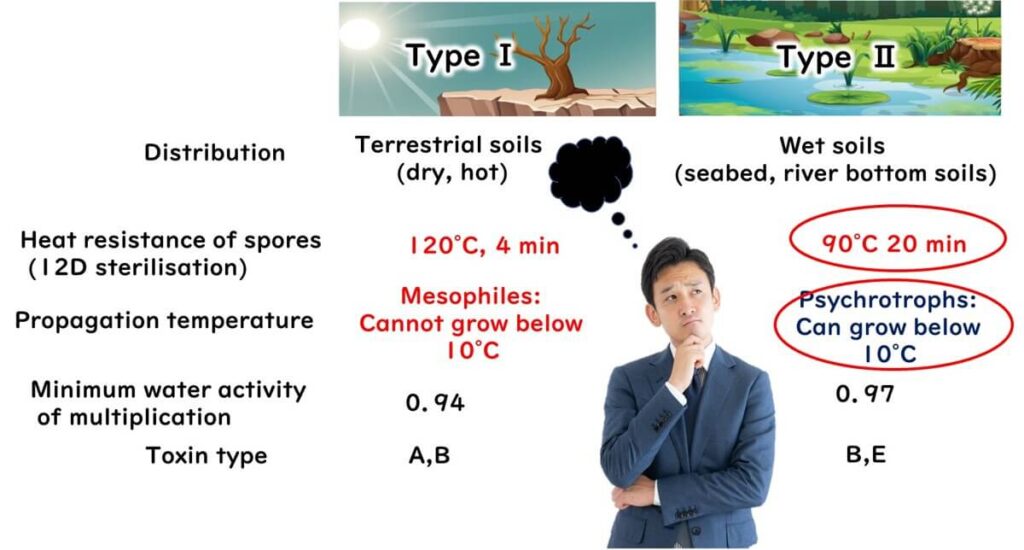

However, Type II botulinum, which can grow at low temperatures, still proliferates even with chilled distribution. But, the heat resistance of Type II spores is less than that of Type I. While Type I requires 121.1°C for 3 minutes to reduce spore count by twelve orders of magnitude, Type II only needs 90°C for 20 minutes.

Some readers might question whether spores that are killed at 90°C for 20 minutes should truly be considered heat-resistant. Nevertheless, this temperature is significantly higher than that used for pasteurization.

Understanding this requires knowledge of the 'Z-value' concept. Calculating with a Z-value of 8°C below 100°C, a heat treatment of 90°C for 20 minutes equates to 200 minutes at 82°C, or about 3.3 hours, and 33 hours at 74°C, or about 1.4 days. At 66°C, it translates to 14 days. From this, we can see that the amount of heat applied in 20 minutes at 90°C is significantly greater than heating at 63°C for 30 minutes, which would substantially impact the flavor and taste of the food.

So, what happens if we aim to make tastier products? During my time researching botulinum risks at university, I frequently consulted with companies eager to create more flavorful and aromatic packaged foods. Unfortunately, choosing not to heat at 90°C for 20 minutes poses a considerable challenge because Type II can grow even at refrigerator temperatures, i.e., below 10°C. Therefore, simply using chilled distribution is not a solution. Of course, the shelf life set during chilled distribution might allow the development of such products without botulinum risk. However, these products would require strict control over distribution temperatures and shelf lives, which realistically raises significant hurdles. While it is possible to create consumer-appealing products, the risk of botulinum poisoning looms large for developers.

The simplest solution might be to ensure continuous cold chain distribution at or below 3.3°C from production to consumption, as Type II cannot grow below this temperature. However, maintaining such stringent control over the distribution temperature from production to end consumers is highly challenging in reality.

In conclusion, as things stand, there is no option but to apply heat treatment at temperatures above 90°C for at least 20 minutes. If a consistent cold chain network at temperatures below 3.3°C can be established in the future, it may become feasible to enjoy tastier packaged foods.