In this detailed article, we revisit the significance of Standard Plate Counting (SPC), a fundamental microbiological test integral to food safety practices. Often referred to as Mesophilic Count or Aerobic Plate Count, SPC measures bacteria in food samples that grow aerobically at mesophilic temperatures. However, it's crucial to acknowledge its limitations, such as not detecting certain microbial groups like anaerobes or microaerophiles. This exploration discusses the intricacies of SPC, its application under various international standards, and its role not as a definitive indicator of food poisoning risk but as a vital tool in assessing the sanitary handling and temperature management of food products.

What is Standard Plate Counting?

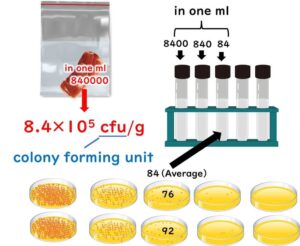

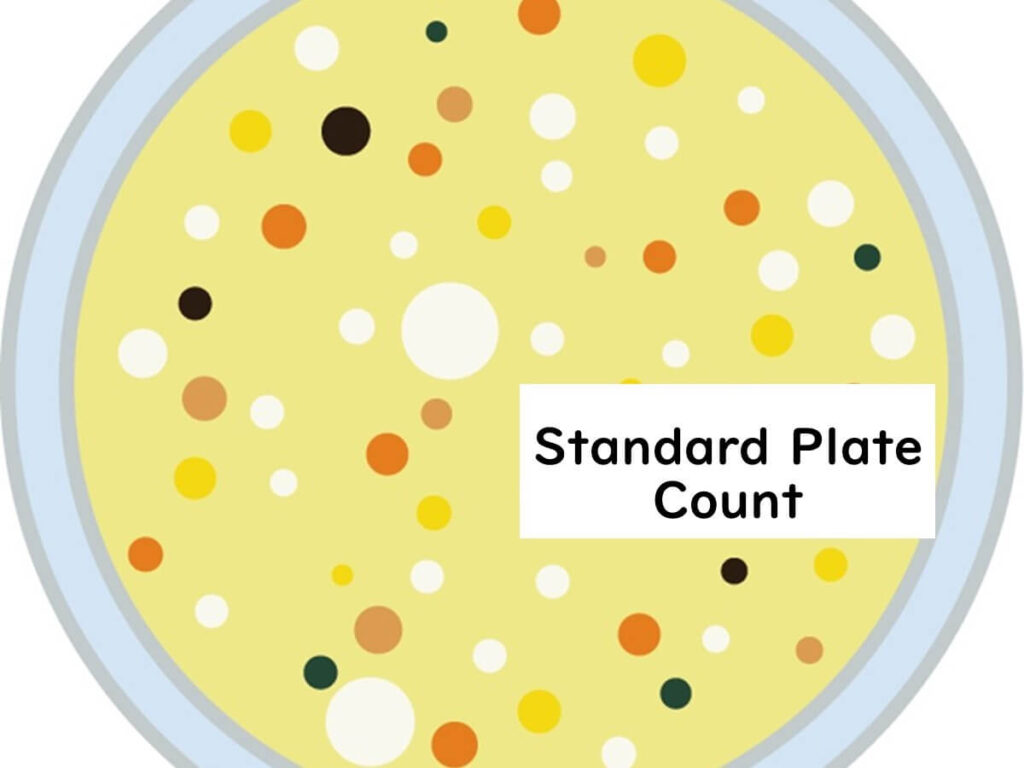

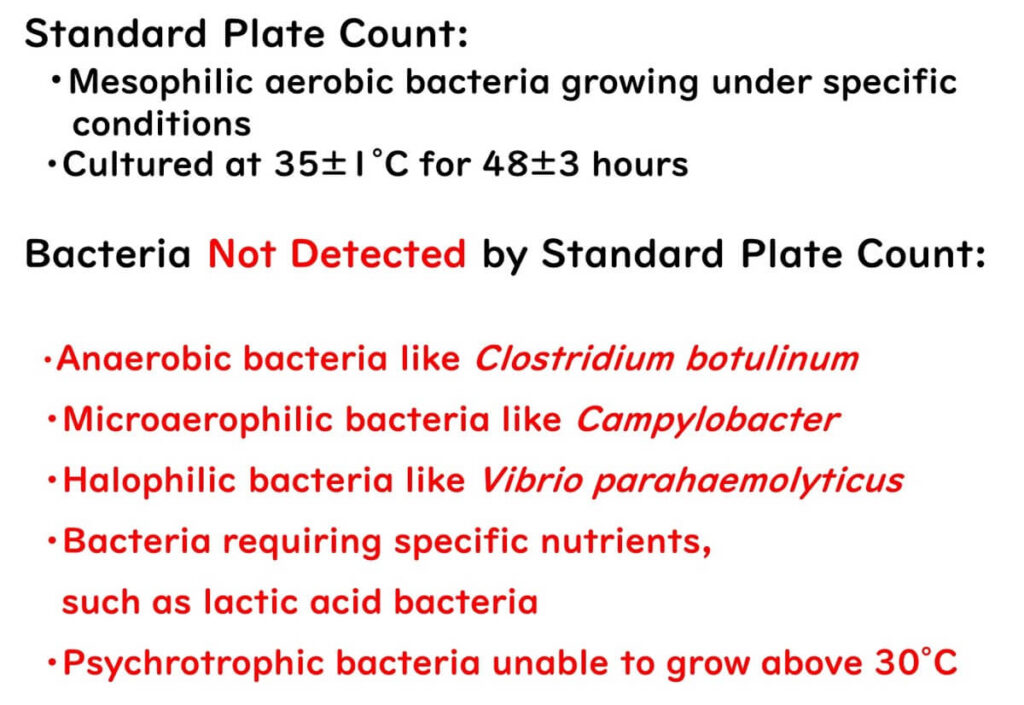

Standard Plate Count (SPC), also known as Mesophilic Count or Aerobic Plate Count (APC), is a method used to measure the microbes present in food samples using an agar medium that contains peptone nutrients suitable for the growth of virtually any type of microorganism. This method is based on the assumption that each cell will form a visible colony on the agar medium. Hence, Standard Plate Count primarily measures certain bacteria in food samples that grow aerobically at mesophilic temperatures (25-40°C).

In terms of culturing conditions for Standard Plate Count, the ISO and EU standards specify a temperature of 30°C for 72 hours. In the USA and Japan, the conditions are set at 35°C for 48 hours.

However, Standard Plate Count does not measure the following types of microbial groups:

- Anaerobic bacteria like Clostridium botulinum

- Microaerophiles like Campylobacter

- Halophilic bacteria like Vibrio parahaemolyticus

- Bacteria that require special nutrients, such as lactic acid bacteria

- Psychrophilic bacteria that cannot grow at 35°C

These limitations highlight that while Standard Plate Counting is a useful tool, it doesn't capture all microbial life forms in food samples.

Standard Plate Count Standards and the Distinct Issue of Food Poisoning Risk

Standard Plate Count (SPC) cannot be considered an indicator from the perspective of food poisoning risk.

Certainly, food samples showing a markedly high Standard Plate Count can be treated as potentially unsanitary if no concurrent tests for pathogens have been conducted. However, a high SPC does not guarantee the absence of food poisoning bacteria.

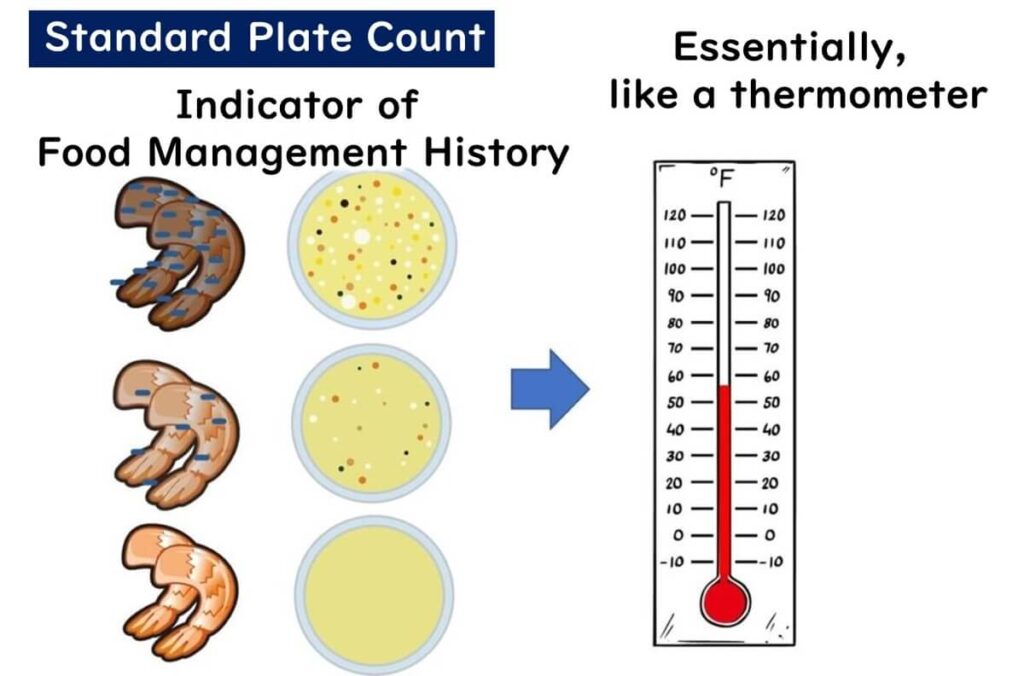

Standard Plate Count primarily serves as an indicator of the sanitary handling history of the food, particularly its temperature management.

Furthermore, the acceptable levels for Standard Plate Count vary depending on the type of food. For instance, it is normal for fresh fish or vegetables to show SPC values between 10^3 and 10^4 cfu/g. A lower count may suggest that some form of sterilization or disinfection has been applied.

Conversely, if a food product that has undergone heat treatments like pasteurization shows a high Standard Plate Count, this could indicate issues such as secondary contamination or inadequate sterilization processes at the food manufacturing facility.

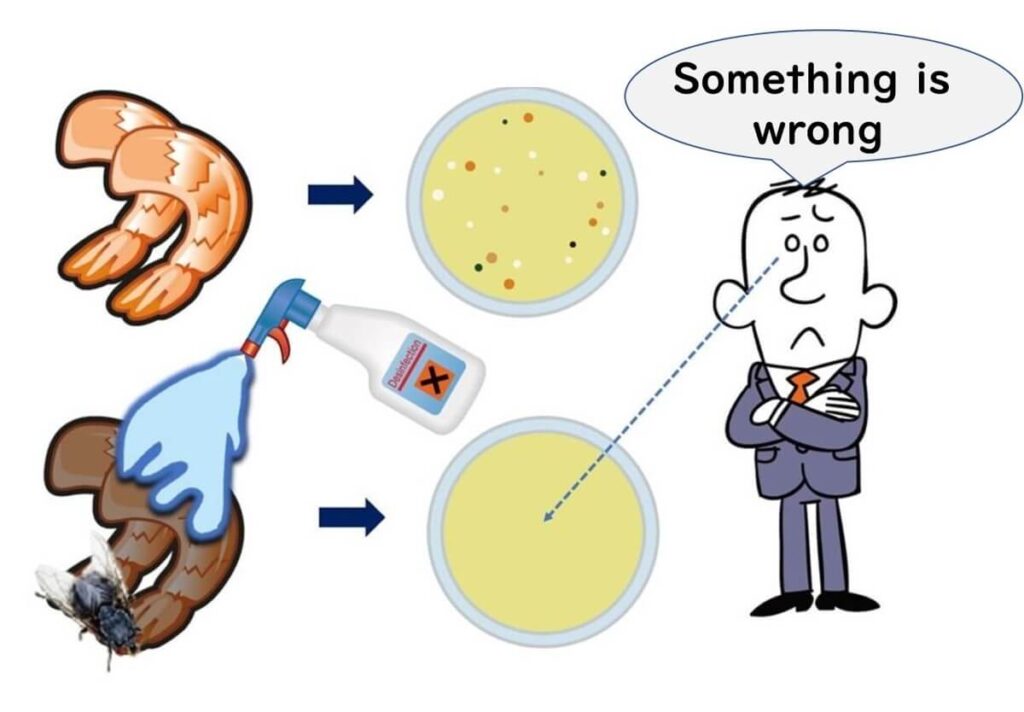

Standard Plate Count is Merely an Indicator, Disinfection is Not the Solution

I have visited several food factories that processes seafood on multiple occasions. There, I frequently observed the use of sodium hypochlorite for cleaning seafood. Naturally, because food standards for import and export stipulate a certain Standard Plate Count (SPC), such measures by exporters are understandable. However, in conversations with quality control managers, it appears there's a prevailing belief that simply lowering the SPC is beneficial.

But targeting SPC as an enemy and striving to lower it at any cost is a fundamental misunderstanding of what the Standard Plate Count actually signifies.

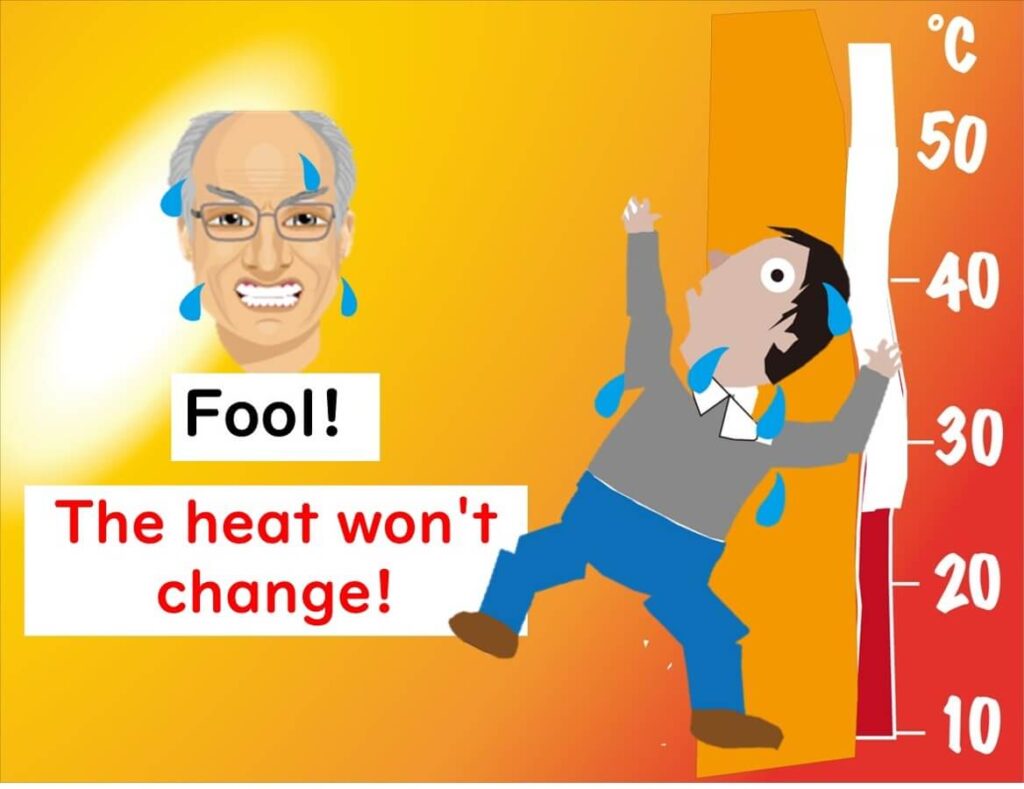

Using disinfectants to merely reduce the SPC is akin to lowering the indicator on a thermometer because it’s too hot outside. Imagine if, due to high temperatures, someone tried hard to manually lower the readings on a thermometer.

Lowering the thermometer's readings won’t change the actual temperature. Similarly, attempting to lower the Standard Plate Count through sterilization does not inherently improve the quality of the product. Even if a low SPC is achieved, it doesn’t necessarily mean the product's quality has improved.

In conclusion, it is crucial to reiterate that Standard Plate Count is an indicator of hygiene in food handling. Repeated for emphasis: SPC is a quality indicator, and disinfecting to alter it doesn’t hold much value.

However, for Heat-Processed Foods, It Serves as a Hygiene Management Indicator

Certainly, from a food safety perspective, pathogenic bacteria must not be present, necessitating sterilization and disinfection processes. However, the prevalence of food poisoning bacteria in products is not high. Therefore, testing for these pathogens directly to verify the effectiveness of heat sterilization is not efficient. Thus, measuring Standard Plate Count (SPC) can be an effective way to validate the efficacy of these sterilization processes.

If there is an understanding that Standard Plate Count measurement is conducted for such purposes, then it is deemed appropriate.

For example, in products like sausages or processed fish products, which should virtually have no detectable SPC immediately after heat processing, finding bacteria levels at 10^5 cfu/g would indicate either a failure in the heating process or a lapse in subsequent hygiene management.

In such cases, measuring Standard Plate Count holds significant importance.

Additionally, SPC measurements can also be effectively used in other contexts such as:

- Using Standard Plate Count as a means to assess the appropriateness of process control in the production of heat-treated or dried foods.

- Checking the condition of incoming carcasses in meat processing, using SPC to assess the hygiene status of the meat supplied.

- Using Standard Plate Count to evaluate the cleanliness of equipment and utensils within a food manufacturing facility.

Summary

To reiterate, from the perspective of food quality, simply reducing the Standard Plate Count through sterilization or disinfection does not inherently improve the quality of the product. It's crucial to understand that a food item that has shown an increased Standard Plate Count, regardless of how effectively the bacterial count is reduced through subsequent sterilization processes, does not revert in quality. The initial poor quality remains unchanged. This emphasizes the importance of maintaining good hygiene practices from the start to ensure high-quality food production.