Listeria monocytogenes is a notorious risk in food processing facilities, particularly known for forming biofilms that make it hard to eliminate entirely from ready-to-eat (RTE) products. A promising solution gaining attention in the US is the combined use of nisin and organic acids during distribution. This article delves into how this method helps control Listeria monocytogenes in RTE foods, enhancing their safety.

Controlling Listeria monocytogenes Growth in Ready-to-Eat Egg Products

In the US, "ready-to-eat" egg products like egg patties, omelets, and scrambled eggs are usually heated to 85°C. This heating process far exceeds the USDA FSIS(2020)recommended pasteurisation, which reduces Salmonella by 5 logs and significantly lowers L. monocytogenes as well.

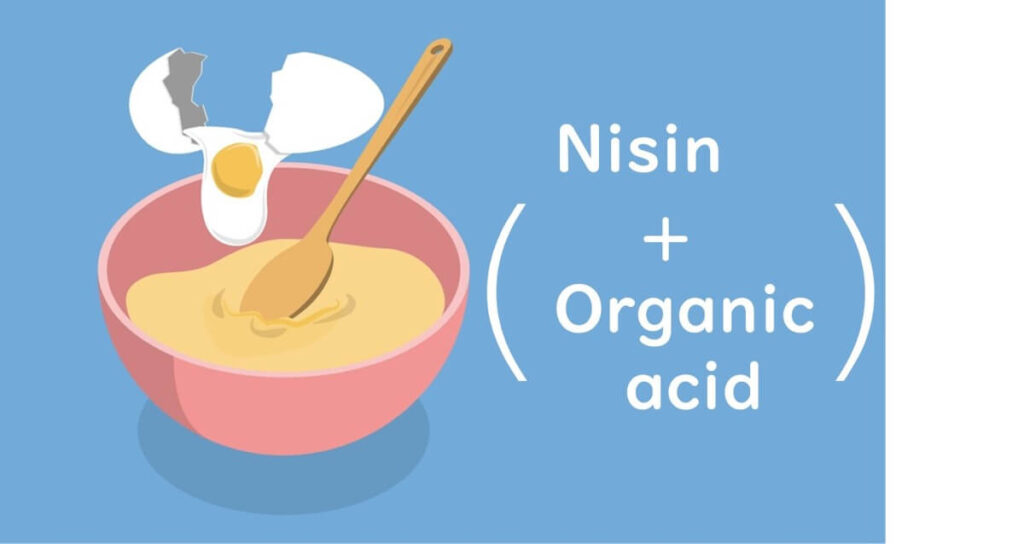

Despite rigorous heat treatment, the risk of post-cooking contamination with L. monocytogenes remains. Hence, effective measures to control its growth are essential. Cargill, a multinational corporation in various sectors, has researched this. Dr Subash Shrestha's study explores improving the safety of RTE foods using nisin and organic acids.

Subash Shrestha et al.,

Ready-to-eat egg products formulated with nisin and organic acids to control Listeria monocytogenes

J Food Prot, 2023 May;86(5):100081. doi: 10.1016/j.jfp.2023.100081. Epub 2023 Mar 28., open access

L. monocytogenes Control Experiments in Ready-to-Eat Egg Products

Experimental Overview:

- Samples: Sterilised liquid whole eggs, refrigerated and processed within seven days.

- Ingredients: Mixed with water, soybean oil, starch, dried milk, xanthan gum, and salt.

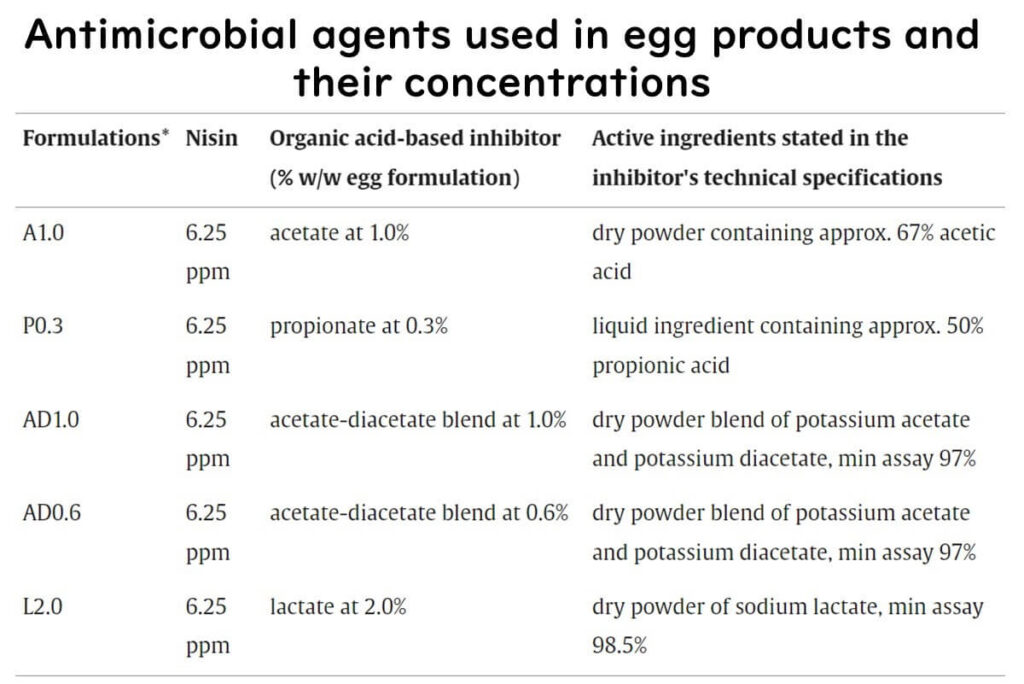

- Nisin Addition: All egg products contained 6.25 ppm of nisin (the USDA allows up to 6.25 ppm in egg products).

- L. monocytogenes Inoculation: Surface-inoculated with L. monocytogenes, then packed in pouches with 20:80 CO₂ and stored at 4.4°C for eight weeks.

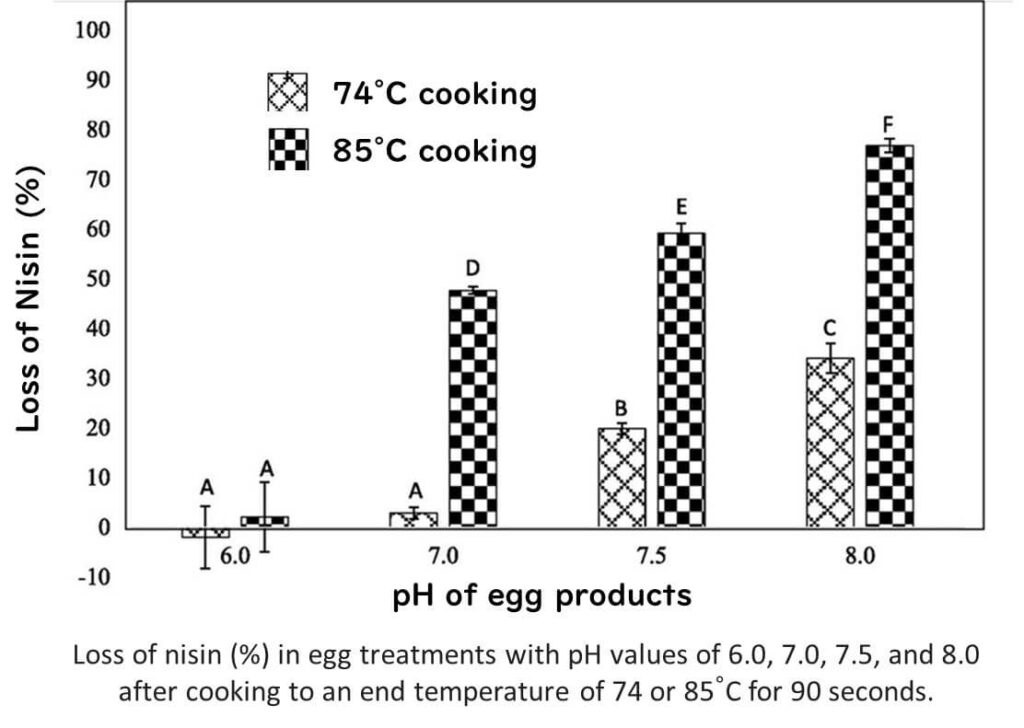

- The study evaluated nisin's stability across various pH levels (6.0, 7.0, 7.5, 8.0) in eggs cooked at either 73.9°C or 85°C for 90 seconds, using bioassay tests. The tests measured the inhibition zones on agar plates inoculated with nisin-sensitive bacteria to determine nisin's activity.

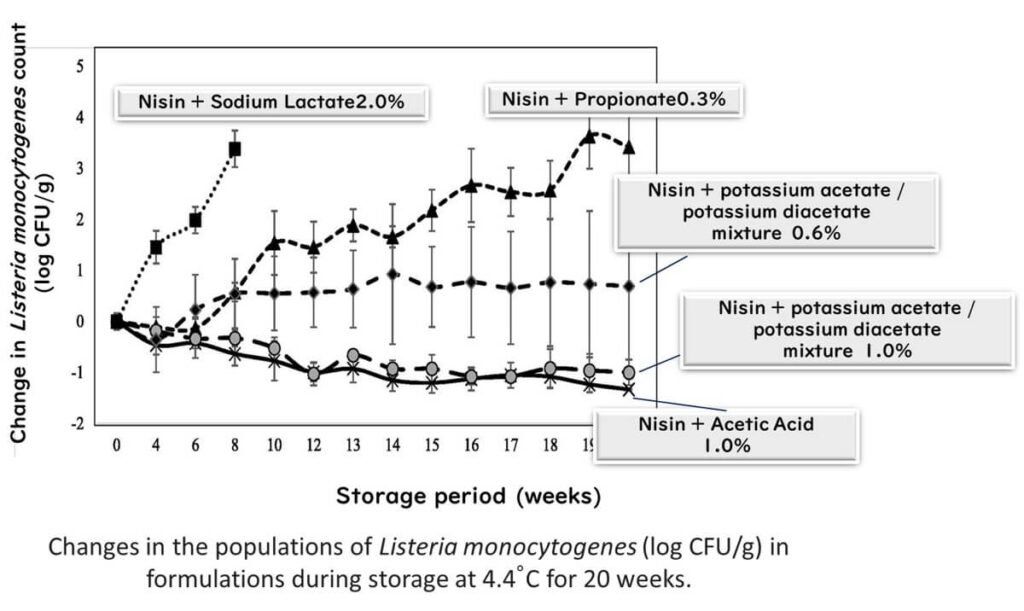

Different organic acids were also tested in combination with nisin:

- Acetic acid (1.0% w/w)

- Propionic acid (0.3%)

- Diacetate (1.0% and 0.6%)

- Lactic acid (2.0%) as a positive control

The figures above are published directly from the referenced paper under the Creative Commons license (CC BY-NC-ND 4.0). To enhance clarity for readers, some explanations have been enlarged.

Experimental Results:

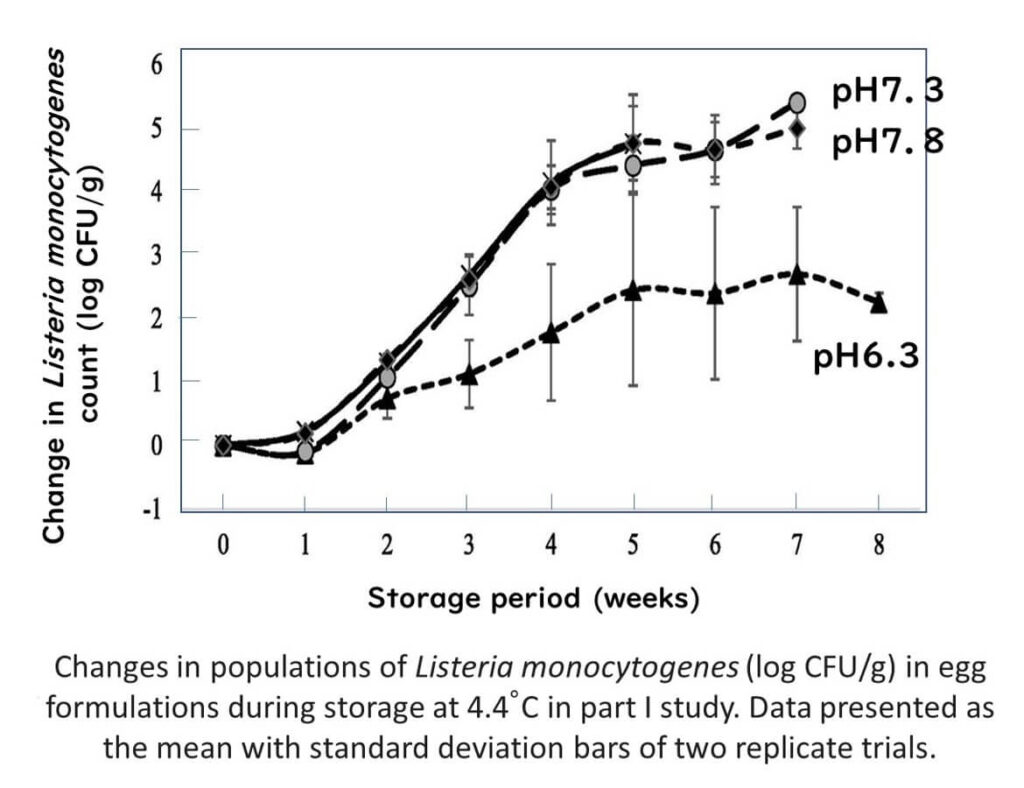

- pH 6.3 Condition: RTE eggs with 6.25 ppm nisin stored at 4.4°C showed less than a 2-log increase in L. monocytogenes after four weeks.

- pH 7.3 and 7.8 Conditions: L. monocytogenes grew by 4 logs in four weeks, similar to products without nisin.

The figures above are published directly from the referenced paper under the Creative Commons license (CC BY-NC-ND 4.0). To enhance clarity for readers, some explanations have been enlarged.

- Nisin Stability: As pH increased from 6 to 8, nisin's degradation accelerated. Higher cooking temperatures (85°C) further reduced nisin's activity.

TThe figures above are published directly from the referenced paper under the Creative Commons license (CC BY-NC-ND 4.0). To enhance clarity for readers, some explanations have been enlarged.

- Combination with Organic Acids: Acetic acid (1.0%) and diacetate (1.0%) completely inhibited L. monocytogenes growth over 20 weeks at 4°C, whereas lactic acid (1.0%) and propionic acid (0.3%) were less effective.

The figures above are published directly from the referenced paper under the Creative Commons license (CC BY-NC-ND 4.0). To enhance clarity for readers, some explanations have been enlarged.

Key Findings from the Experiment

In the US, nisin is approved as an antimicrobial agent for egg products under USDA FSIS Directive 7120.1. Organic acids like propionic, lactic, and acetic acids are also widely used in food preservation.

This experiment revealed:

- pH Impact on Nisin: Lower pH enhances nisin's antimicrobial effect. Although moderately effective alone, combining nisin with organic acids is more efficient.

- Temperature and pH Influence: Higher pH and cooking temperatures reduce nisin's activity. Maintaining lower pH during production helps preserve its efficacy.

- Best Combination: Nisin with acetic acid-based preservatives effectively inhibited L. monocytogenes growth for 20 weeks at 4°C.

Dr Shrestha and colleagues concluded that their research is the first to demonstrate the effectiveness of combining nisin and organic acids to control L. monocytogenes in refrigerated egg products.

My Take on This Study

From my perspective, the key takeaway is how dramatically pH influences the antimicrobial performance of nisin in real food matrices. What struck me most in this study is the clear demonstration that even a permitted concentration of nisin (6.25 ppm) loses much of its effectiveness at neutral to alkaline pH levels and elevated cooking temperatures—conditions not uncommon in RTE egg processing.

This finding has significant practical implications. It challenges the assumption that nisin is robust under all typical food processing conditions. Quality assurance professionals should be particularly aware that unless pH is carefully controlled, nisin alone may not be sufficient to inhibit L. monocytogenes post-processing.

I also found it noteworthy that acetic acid, often considered a less sophisticated preservative, outperformed lactic acid in this context. This contradicts much of the conventional understanding in food microbiology, where lactic acid is generally held in higher regard for antimicrobial efficacy. From a QA perspective, such results highlight the need to re-evaluate ingredient choices based on actual product formulation and storage conditions rather than traditional assumptions.

This aligns with what I have seen in food industry settings: the combination of multiple hurdles—such as pH control, antimicrobial agents, and cold storage—is far more effective than reliance on a single intervention. It confirms what I’ve long emphasised: that food safety depends on the interactions between ingredients, processing parameters, and storage, not merely the presence of a permitted additive.

Summary and Further Reading

For controlling L. monocytogenes in RTE foods, the strategy involves:

- Lowering pH as much as possible.

- Combining nisin with organic acid preservatives.

Why?

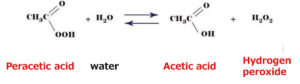

- Nisin: Becomes positively charged at lower pH, enhancing its attachment to negatively charged microbial cells.

- Organic Acids: Become more hydrophobic at lower pH, allowing easier penetration of microbial cell membranes.

Nisin was approved as a food additive in Japan in 2009 and must be labelled as a preservative. For more on nisin and organic acids as antimicrobials, check the related articles on this blog.

A Natural Antimicrobial Agent Transforming Food Preservation and Medicine

Additionally, for a detailed overview of the basics of organic acids as antimicrobials, please refer to the article linked below on this blog.

How pH Influences Microbial Growth and Organic Acids as Antimicrobials