Gram Staining: Principles, Methods, and Procedures

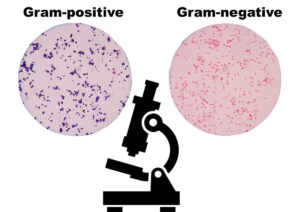

Gram staining is a cornerstone technique in bacteriology, widely used to classify bacteria into Gram-positive and Gram-negative groups based on cell wall structure. In this article, we provide a concise overview of its principles, step-by-step procedures, and interpretation of results. While this guide is aimed at beginners in food microbiology, it serves as a practical resource for understanding the fundamental aspects of Gram staining without delving into exhaustive experimental details.

Understanding the Differences between Gram-Positive and Gram-Negative Bacteria: A Summary of Key Learnings

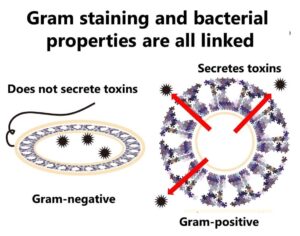

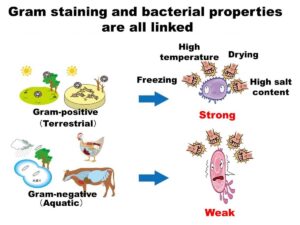

Understanding the unique characteristics and habitats of Gram-positive and Gram-negative bacteria is essential for comprehending their role as foodborne pathogens. While Gram-positive bacteria are often associated with toxin production, Gram-negative bacteria are primarily linked to infection-type foodborne illnesses. This article provides a clear summary of their differences, exploring their physical and chemical properties, habitats, and relevance in food safety. It also addresses common misconceptions about their ecological niches and offers insights into their adaptability to various environments, including moist terrestrial settings.

Infection-Type and Toxin-Type Foodborne Pathogens

Foodborne pathogens are a significant concern for public health, particularly in the food industry. These pathogens can be classified into two main categories: toxigenic and infectious. Understanding their differences is crucial for effective prevention and control measures. Toxigenic pathogens, often associated with Gram-positive bacteria, produce harmful toxins that cause illness when consumed. In contrast, infectious pathogens, typically Gram-negative, invade the human body and cause symptoms through direct interaction with the intestinal system. This article explores the distinctions between these two types of pathogens, their mechanisms, and their implications for food safety.

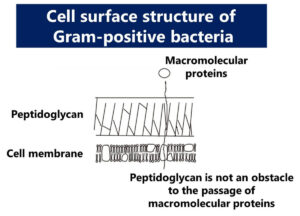

Chemical Resistance: Structural Differences Between Gram-Positive and Gram-Negative Bacteria

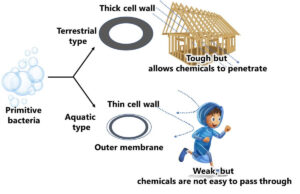

The ability of bacteria to resist chemical substances is intricately tied to their cell surface structures. This page explores how the structural differences between Gram-positive and Gram-negative bacteria impact their resistance to chemical agents, providing crucial insights for understanding bacterial behavior in various environments, including food safety and microbiology applications.

Structural Differences in Gram-Positive and Gram-Negative Bacteria: Key Insights for Food Safety

The structural distinctions between Gram-positive and Gram-negative bacteria are fundamental to their characteristics, habitats, and responses to environmental stressors. This article delves into these differences and their implications for food hygiene management, providing essential knowledge for professionals in food safety and microbiology.

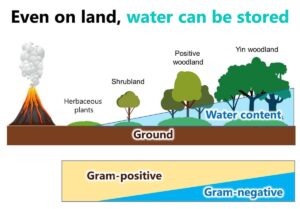

Survival Strategies of Gram-Positive and Gram-Negative Bacteria in Dry and Wet Environments

Bacteria have adapted to various environments over millions of years, with Gram-positive and Gram-negative bacteria displaying unique survival strategies in dry and wet conditions. This article explores how these differences impact their behavior in everyday environments, such as food factories and natural habitats, offering insights into their roles in microbiology and food safety.

A Comprehensive Guide to Gram-Negative and Gram-Positive Bacteria: Key Differences and Environmental Adaptations

Understanding the unique characteristics of Gram-negative and Gram-positive bacteria is essential for professionals and enthusiasts in food microbiology. This page explores their structural differences, environmental preferences, and implications for food safety. Learn how these bacteria thrive in various conditions and how they influence foodborne illnesses, hygiene practices, and more.

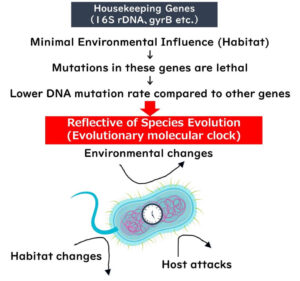

Streamlined Molecular Methods for Microbial Identification: A Practical Guide

Molecular methods have revolutionized microbial identification, offering precise tools to define bacterial species and uncover operational taxonomic units (OTUs). In this guide, we demystify the complexities of techniques like 16S rRNA and 16S rDNA sequencing, explaining their significance in identifying species and their role in phylogenetic analysis. From understanding housekeeping genes to selecting ideal genetic regions for analysis, we’ll also delve into the benefits, limitations, and practical considerations. Join us as we explore these powerful tools for microbiological testing, tailored for professionals in the food and safety industries.

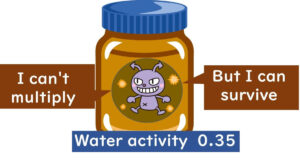

Peanut Butter and Salmonella: Key Lessons from Foodborne Illness Cases

Peanut butter, with a water activity level of 0.35 or less, is generally an unlikely environment for bacterial growth. Hence, it was not traditionally seen as a food prone to bacterial food poisoning. However, from 2006 to 2012, the United States experienced three major Salmonella outbreaks linked to peanut butter. At the time, President Obama appeared on NBC and made critical remarks about the FDA. This article presents an example of a study analysing the causes of one of these outbreaks.

DNA Testing vs. Culturing in Microbiology: Speed, Accuracy, and Global Data Compatibility

Unveil the magic of genetic testing in microbiology—a swift and precise upgrade from the traditional, slower culturing methods. Imagine genetic testing, especially PCR, as a high-speed copier that zaps genes into numerous copies in no time, while traditional culturing is more like assembling a house brick by painstaking brick. This article draws vibrant analogies to show how DNA’s rock-solid consistency and the universal language of its data propel genetic testing to the forefront of reliable identification. It’s a game-changer in tracking contamination, particularly in the food industry, revolutionizing safety standards across labs and conditions. Dive into this comparative exploration that not only demystifies cutting-edge technology but also illustrates its seamless integration with traditional methods, boosting both their prowess and precision.