HACCP (Hazard Analysis Critical Control Point) is a system designed to ensure food safety by preventing hazards before they occur, rather than relying solely on final product testing. This approach shifts the focus from microbial testing to process control, where risks are managed proactively at key points in food production.

But how does this system reduce the need for microbial testing? This article explores the fundamental concepts behind HACCP and how it has changed food safety management.

What is HACCP?

This article does not delve into the details of HACCP (Hazard Analysis Critical Control Point) itself. However, to understand how microbial testing fits into HACCP, it is essential to grasp the basic concepts of HACCP, particularly its relationship with microbial testing.

HACCP stands for Hazard Analysis Critical Control Point, a system that identifies hazards (HA) in food production processes and establishes critical control points (CCP) to prevent these hazards. In essence, HACCP involves identifying potential hazards in food manufacturing, setting up key control points to mitigate them, and implementing systematic controls.

How Useful is Microbial Testing in Food Production?

Fundamentally, HACCP aims to render microbial testing of food unnecessary. But why is this?

Consider a haystack that serves as feed for your valuable cow. If there's a possibility that a needle is mixed into the hay, swallowing it could be fatal for the cow. What would you do?

Checking a handful of hay and not finding a needle does not guarantee safety. To be certain, you would need to inspect the entire haystack, which is known as full inspection.

While full inspection might be feasible for hay, what about food products? Imagine there is a possibility that some products in a food factory contain food poisoning bacteria. Conducting a full inspection would mean destroying all products, which is clearly impractical.

Differences Between Chemical and Microbial Analysis

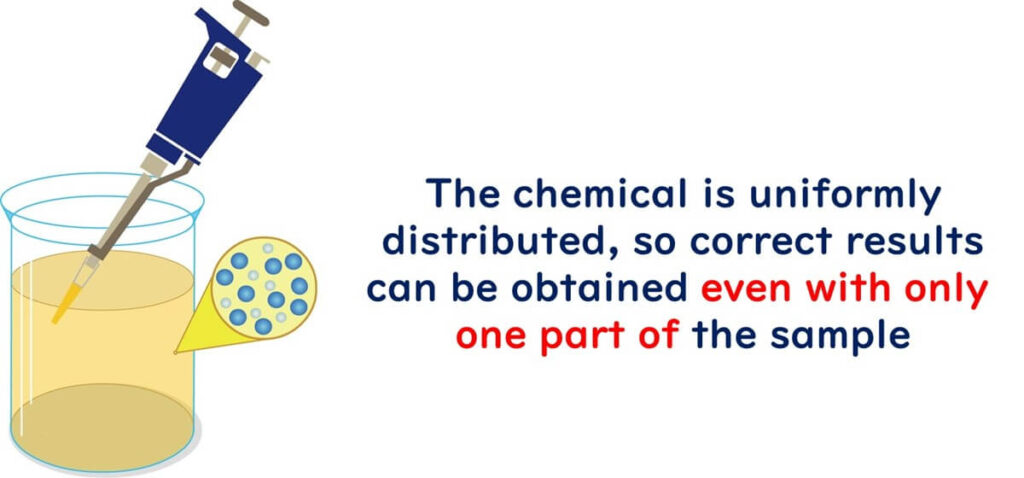

There is a significant difference between microbial testing and chemical analysis.

- Chemical Analysis: If you need to measure the concentration of a substance in a beaker, extracting 1 ml and measuring its concentration allows you to determine the concentration of that substance in the entire beaker. This is because chemical substances are homogeneously distributed.

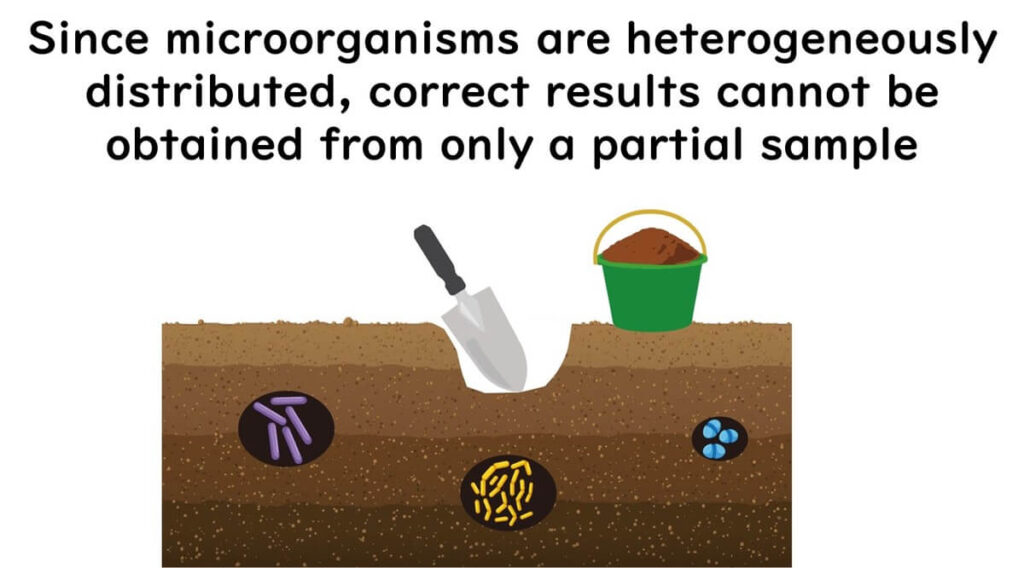

- Microbial Analysis: Unlike chemicals, microorganisms are often unevenly distributed. A single microbial cell divides and forms clusters, making it difficult to predict contamination through spot checks.

For detailed calculations of the accuracy of microbial testing in food, refer to our article explaining the purpose and accuracy of microbial testing.

The Emergence of HACCP to Address the Shortcomings of Microbial Analysis

s mentioned earlier, ensuring safety through microbial testing of the final product has its limitations. This is where HACCP comes into play. HACCP fundamentally aims to eliminate the need for final testing by thoroughly managing the manufacturing process.

HACCP was developed by NASA, where foodborne illnesses in space are unacceptable. Even with rigorous microbial testing, a statistical chance of foodborne illness remains. Thus, HACCP was devised as a method to eliminate microbial risks through strict process control rather than relying solely on testing.

A Method to Eliminate Final Testing by Thorough Process Control

To explain HACCP simply:

Imagine an athlete participating in the Olympic 400m relay. He stands at the start line, already certain in his mind that he will win. He believes that the race itself is almost unnecessary because he is confident of winning gold. But why does he have such confidence?

This athlete has trained based on HACCP principles.

The first step of HACCP is Hazard Analysis (HA). A hazard is the greatest potential negative event that must be avoided.

Initially, this athlete is unrivaled in straight-line speed. However, he has repeatedly fallen during cornering, costing him medals. For him, the hazard (HA) is the risk of failing at cornering.

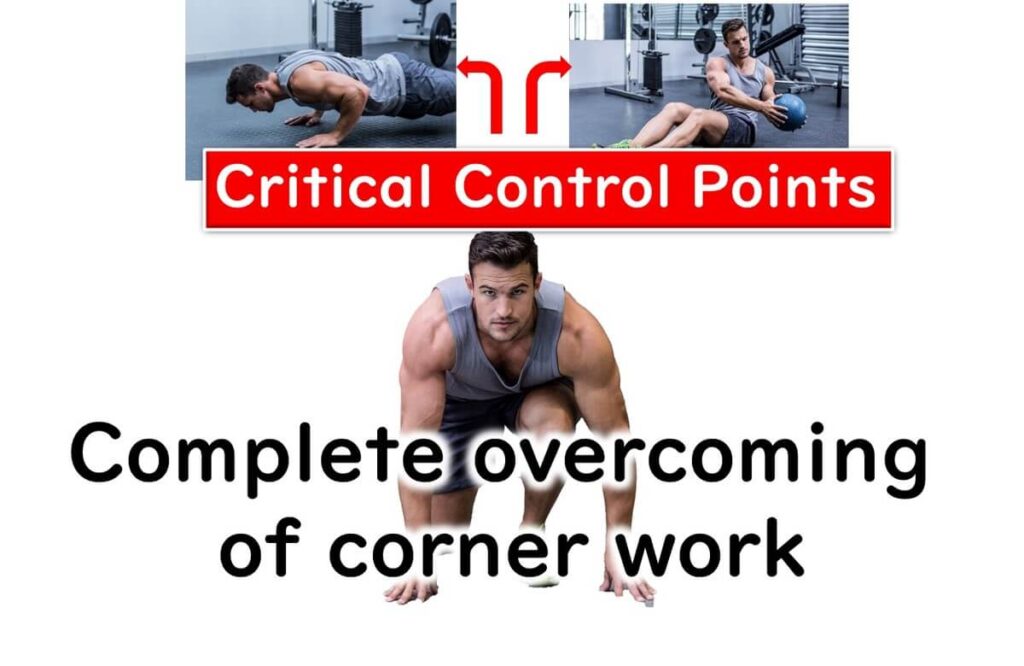

The next important concept is Critical Control Point (CCP). What must be done to prevent this hazard? The answer is to develop the muscles and techniques required to run corners effectively. By rigorously implementing CCPs up to the Olympics, he is confident of winning even before the race begins.

This is the essence of HACCP.

Returning to the earlier analogy of the needle in the haystack: by managing the hay with HACCP principles, it becomes certain that no needle could ever enter the haystack. This level of management is what HACCP achieves.

Critical Control Points (CCPs) Must Be Simple

A crucial aspect of HACCP is keeping the CCPs straightforward. For example, suppose water is leaking from various holes in a bucket.

Plugging each hole in the bucket? No, that is not a CCP.

Turning off the water supply solves the problem immediately. This is the critical control point.

Thus, in CCP, focusing on the key elements is essential.

📌 Read Part 2: Essential Microbial Testing in HACCP: What Remains Necessary?– Coming Next Week!